0 Introduction

Under the guide of the “double-carbon” target and the national energy strategy in China,the proportion of development and utilization of clean energy,such as solar energy,has increased yearly [1].Developing hydrogen production from electrolytic water using renewable energy compensates for the shortcomings of intermittent fluctuations in wind and solar power generation [2,3].This technology can convert renewable energy into hydrogen and has the advantages of seasonal,long-term storage,largecapacity storage,high energy density,and cleanliness.The PEMEL has the characteristics of fast response and wide power range [4,5],which is suitable for the above scenario.

In recent years,many studies have been conducted on the operational strategy of coupling renewable energy with PEMEL to produce hydrogen.In [6],a bi-level optimization under the scenario of hydrogen production with wind and solar energy was proposed to determine the optimal capacity and operational strategy by considering the lifeefficiency model of the electrolyzer.In [7],an optimal operation strategy was proposed to make the electrolyzer operate in a high-efficiency range to achieve the best hydrogen production efficiency,minimum operation cost,and carbon emissions.In [8],considering the influence of instantaneous and wide fluctuations of wind power input on an alkaline water electrolyzer,an optimal operation strategy was proposed to obtain maximum hydrogen production.In [9],a multi-objective layered optimal allocation model was established for an integrated energy system containing grid-connected PV,hydrogen,and natural gas.The carbon emissions of the entire system were regarded as the primary objective function,and the economy of the system operation was then considered.In [10],a dynamic efficiency model of the electrolyzer was proposed,which was helpful for optimizing the economic operation of the hydrogen network.

Many studies have indicated that the material components of PEMEL are degraded under fluctuating power input [11-14].The fluctuating power input produces mechanical stress in the PEMEL that damages the membrane.Corrosion of the catalyst layer causes metal ions to dissolve and migrate to the membrane,reducing its conductivity [15].Hydrogen peroxide and hydroxide groups are formed on the cathode side of the membrane under the crossing of hydrogen,and the functional groups of the membrane ionomer are attacked,causing fluoride degradation in the membrane [16].Membrane thinning further affects the conductivity and gas permeability of the membrane.The main reason for the degradation of the anode Ir catalyst is the operation of the electrolyzer under severe working conditions,such as high potential and potential fluctuation [17,18].The better the catalyst activity,the lower the free energy required for the reaction,the greater the exchange current density,and the lower the activation overpotential [19].Bipolar plates,porous transport layers (PTL),and other components easily undergo passivation and corrosion at high potentials.The formation of a titanium oxide film increases the contact resistance and ohmic overpotential of the electrolyzer [20-22].Therefore,when an electrolyzer operates for a long time,it is necessary to consider the performance attenuation caused by degradation and the extra cost of replacing the materials.

In recent years,many studies have been conducted on the fluctuating degradation of proton exchange membrane fuel cells (PEMFC).In [23],a catalyst degradation model for PEMFC was proposed based on an experimental algorithm,and the electrochemical surface area of the catalyst layer under cyclic loading was calculated to measure the catalyst performance.In [24],three parameters were used to calculate the degradation of a PEMFC,and a degradation variable was used to measure the degradation level.In [25],an impedance-based equivalent circuit was designed to model the degradation of a PEMFC,in which the dynamic behavior can be well described.However,studies on performance attenuation models of PEMEL under fluctuating inputs are limited.In reference [26],a linear model was proposed to represent the increase in membrane resistance,and it was pointed out that the degradation mechanism has been studied now;however,there is currently no accurate model to describe the degradation caused by PEMEL fluctuation operation.

Based on a hydrogen production system containing offgrid PV coupled with PEMEL and BESS,this study focuses on the performance attenuation of PEMEL under PV fluctuation power input.It proposes an operation strategy for a hydrogen production system with a comprehensive consideration of hydrogen production efficiency and performance attenuation.The remainder of this paper is organized as follows:

1)Based on the existing research,an attenuation model of the primary material component of the PEMEL under a fluctuating power input is proposed,and the fluctuation condition is mainly considered.

2)Based on the attenuation model,considering the two objective functions of hydrogen production and performance attenuation comprehensively,an optimal operational strategy for PEMEL and BESS is proposed.

3)A multi-time-scale optimization method is proposed based on the optimal operation strategy.The power distribution of the hydrogen production system was optimized at a scale of 1 h,and the operation strategy was optimized at 10 min to minimize the life cycle cost of the entire hydrogen production system.

1 Performance attenuation model of PEMEL

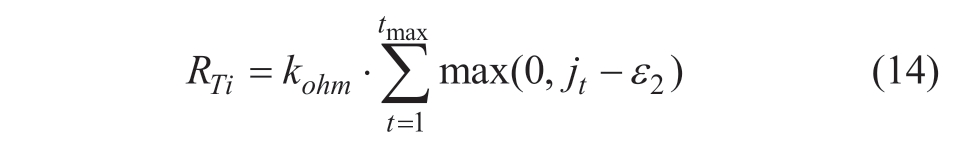

1.1 Basic model of PEMEL

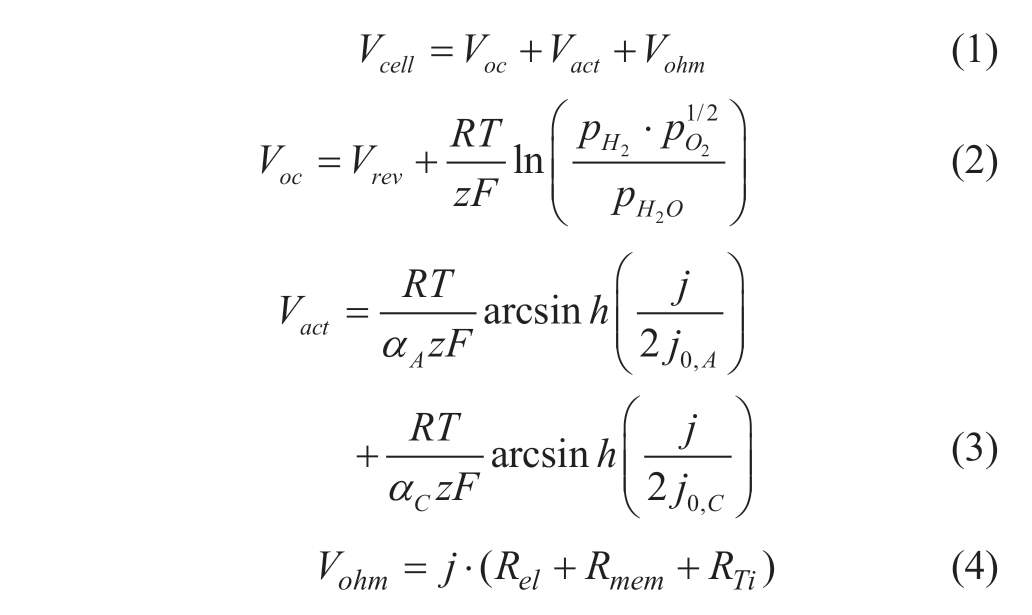

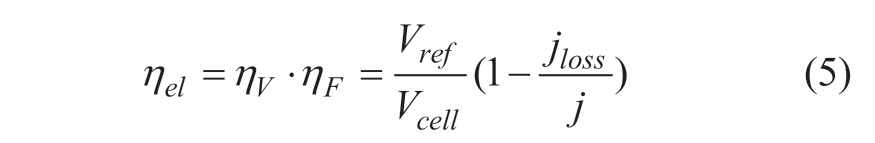

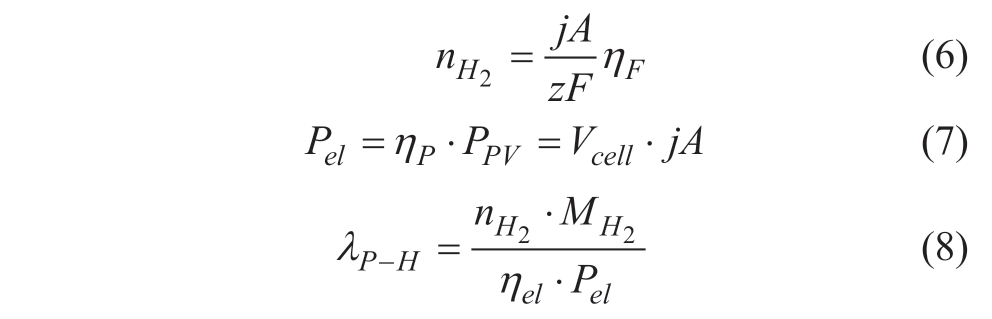

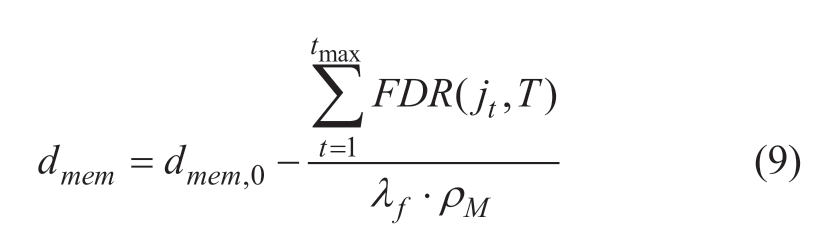

The voltage and efficiency models of PEMEL are typically used in optimization problems [23].The entire voltage range of the PEMEL can be divided into three parts:open-circuit voltage,activation overvoltage,and ohmic overvoltage.The diffusion overvoltage can be ignoredbecause of its small order of magnitude.

where Vrev is reversible voltage,which is a constant value of 1.23 V under standard conditions,R is gas constant,T is the temperature of PEMEL,F is Faraday constant,p is partial pressure,αA is charge transfer coefficient,z is the number of electrons participating in the reaction,j0 is exchange current density,Rel is the resistance of membrane electrode,Rmem is the resistance of proton exchange membrane (PEM),RTi is the resistance of titanium oxidation.

The efficiency of the PEMEL ηel is the product of the voltage and the Faraday efficiencies.Where jloss is the loss current density related to the permeation of hydrogen and oxygen into the PEM.The relationship between the input power and current density in the PEMEL is referred by (5)[23].

According to Faraday’s law,the hydrogen production ηP is proportional to the current density j [23].The efficiency ηP between the electrolyzer and PV power is mainly determined by the power electronic equipment.

where A is the area of the membrane,MH2 is the molar mass of hydrogen,and λP H- is the conversion coefficient of the power and hydrogen.

1.2 Attenuation model of PEMEL

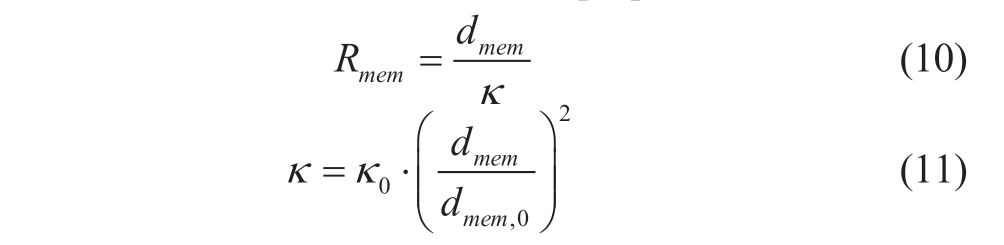

For membrane degradation,the reduction in membrane thickness caused by fluoride release has been considered [16].

where dmem,0 is the thickness of the PEM at the beginning;FDR (jt ,T)is a function of the fluoride degradation rate,which is fitted with a 6-degree polynomial [16];and T is the temperature of the PEMEL.λf is the percentage of fluoride content in the PEM,and ρM is the density of the PEM.

The influence of dmem on the voltage model is mainly reflected in the change in ohmic resistance.In the attenuation model,the corresponding fluoride release rate was obtained based on the input current,and the attenuated ohmic resistance term was obtained [16].

where κ0 is initial membrane conductivity.

For catalyst degradation,it is considered that potential fluctuations lead to a decrease in the catalyst activation performance of the anode iridium catalyst,which finally leads to a decrease in the exchange current density [24].

where Ccl represents the catalyst performance,kdis is the dissolution coefficient,krdp is the re-deposition coefficient,ε1 is the threshold of the potential fluctuation,and  is the exchange current density after degradation.

is the exchange current density after degradation.

The influence of the j0′ on the voltage model is mainly reflected in the change in the activation overvoltage Vact.

For the degradation of the bipolar plate and PTL,it is considered that the ohmic resistance of Ti oxidation is formed under long-term high current densities [22].

Where kohm is the oxidation rate,ε2 is the threshold of high current density.

2 Layered optimization model

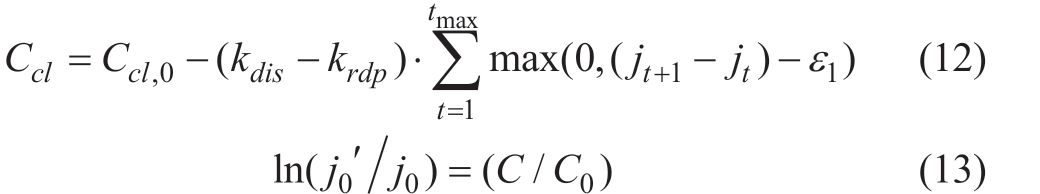

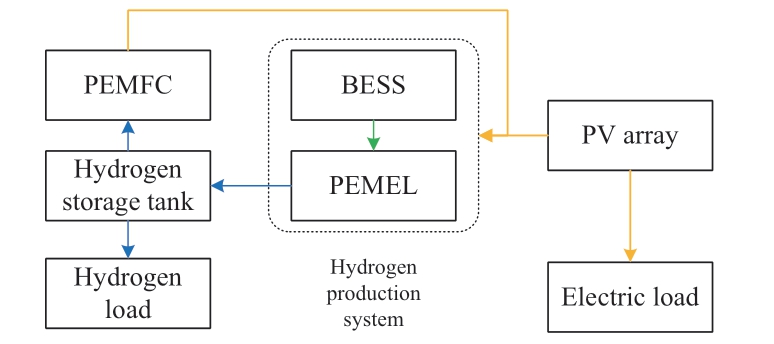

2.1 The structure of hydrogen production system

The hydrogen production system was composed of electric and hydrogen energy flows,which were coupled using PEMEL.The system utilizes surplus PV resources for electrolytic hydrogen production,generating green hydrogen.Considering the storability of hydrogen,a proton exchange membrane full cell (PEMFC)is used to supply power when the PV output is weak.The PV array transfers the remaining output to the PEMEL after meeting an electric load,and the generated hydrogen is directly supplied to the hydrogen load or stored in a hydrogen storage tank.In addition,a BESS was added to undertake power fluctuations to slow down the degradation of the PEMEL.

Fig.1 The structure of hydrogen production system

2.2 Determination of typical scenes

It is computationally intensive to study the scheduling of electric-hydrogen coupling systems throughout the year when the temporal resolution is less than 1 h.Therefore,the typical day method was used to study the single-day power scheduling.To highlight the PV fluctuation,the fluctuation feature extraction method was used to obtain the scene label,and then scenario reduction by clustering was used to obtain the typical PV curves representing different fluctuation degrees.

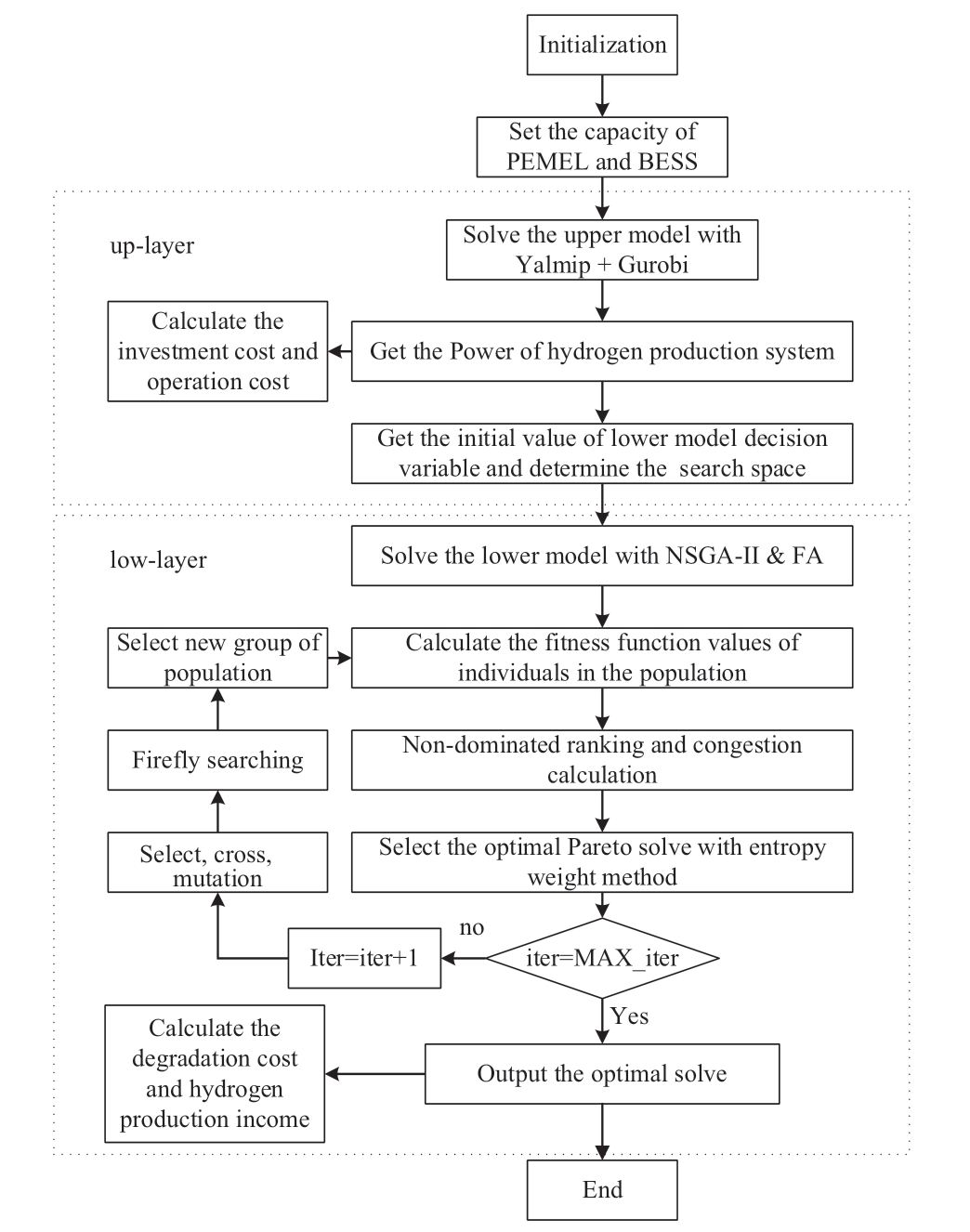

2.3 Layered scheduling optimization

Considering that the scheduling resolution in electric load is mostly 1 h,and the resolution of PV power fluctuation is at the minute level if the global optimization is directly carried out at the minute scale,the search space will be large,and the calculation efficiency will be low.Therefore,a layered scheduling optimization method is proposed in this study.Hour-scale optimization was used to determine the economic power allocation of the PV hydrogen production system,and minute-scale optimization was used to suppress the power fluctuation to slow down the attenuation of PEMEL.

In the up-layer model,the PV hydrogen production system cooperates with the electric load to optimize the electric energy flow.The energy allocation of the hydrogen production system is obtained,and the optimization unit time is set to 1 h.In the low-layer model,the PV hydrogen production system introduces the BESS to stabilize the power fluctuation.The optimal power allocation of PEMEL+BESS is obtained,and the optimization unit time is set to 10 min.

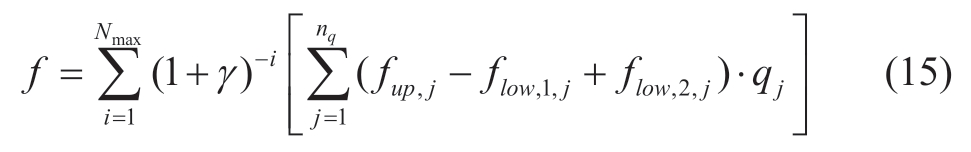

The optimal evaluation index of the hydrogen production system is expressed by its life cycle cost (LCC).The LCC consists of the investment cost,operating cost,replacement cost,and operating income.In the entire system life cycle,referring to the net present value (NPV),the discount rate γ is introduced and the LCC is calculated using (15).

where Nmax is the life of the hydrogen production system,fup j, is the up-layer objective function,flow j,1,,flow j,2, are the low-layer objective functions 1 and 2,qj is the probability of a typical scenario,and nq is the number of typical scenarios.In this study,the process was first optimized for a single typical day,and the annual system cost was calculated according to the proportion of typical days.Considering the performance attenuation of the PEMEL on typical days,the voltage model of the PEMEL was used to calculate the efficiency and attenuation cost.Finally,the LCC is discounted throughout the system cycle.

(1)Decision variables of the upper model

For the upper model,it is necessary to optimize and determine the power sequence of absorbing residual solar energy in the PV hydrogen production system under the 1 h time scale,that is,![]()

(2)Objective function upper model

The upper model mainly determines the residual solar energy that is absorbed by the hydrogen production system at a time scale of 1 h,which is related to the capacity and working power of the hydrogen production system.Thus,the objective function of the upper model is to minimize the investment and operating costs of the system.

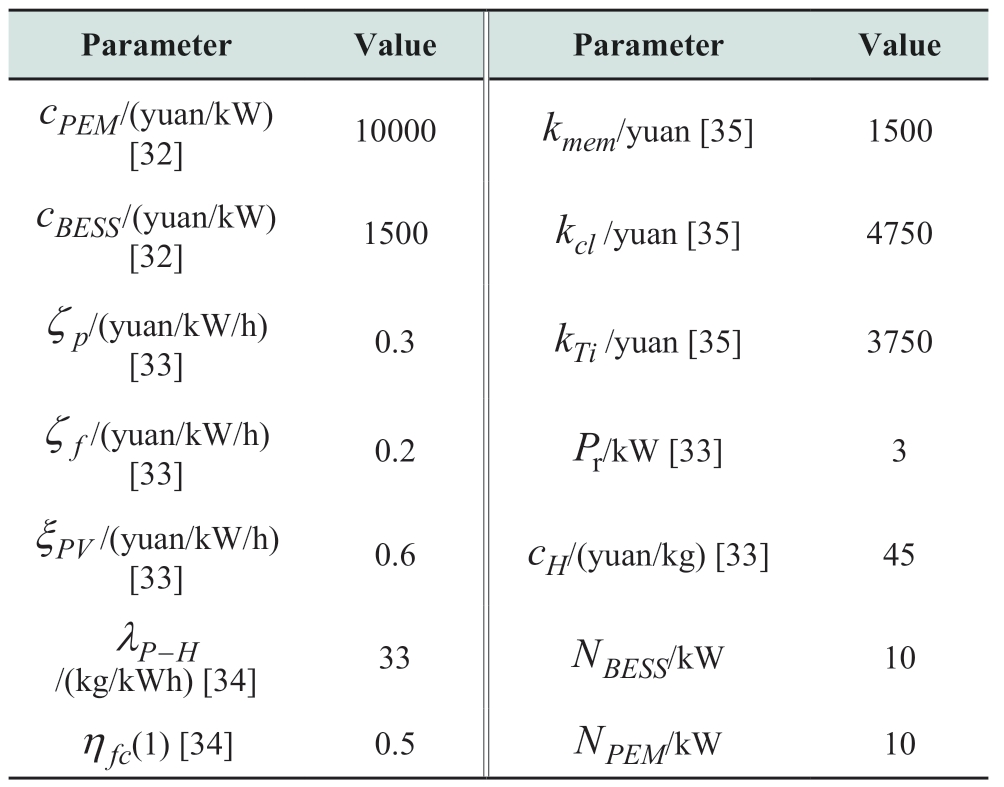

The investment cost Cinv is the capital cost of purchasing PEMEL and BESS during the entire system operation cycle and is proportional to the capacity of the purchased equipment.

where cPEM and cBESS are the purchase price per unit capacity,NPEM and NBESS are the capacities of the PEMEL and BESS,respectively.

The operating costs Cop include the consumption cost of the PEMFC operation and hydrogen production system operation.The consumption cost was directly proportional to the operating power of the hydrogen production system.

where tup,max is the maximum time on the up-layer timescale,ζ p is the coefficient of the hydrogen production system operation cost,and ζ f is the coefficient of the PEMFC operation cost.

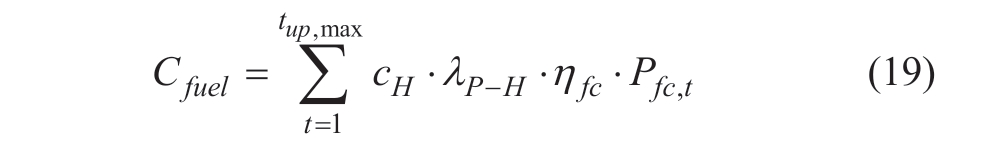

The fuel cost Cfuel is the energy cost of hydrogen.

where cH is the price of hydrogen,ηfc is the efficiency of PEMFC.

The consumption revenue SPV indicates that the hydrogen production system uses PV power to produce green hydrogen,helping the microgrid digest the PV fluctuations.

Where,ξPV is the revenue coefficient of PV fluctuation digest.

(3)Constraint condition of upper model

The first is the power-balance constraint,which satisfies the electric power balance of the PV array output,fuel cell output,hydrogen production system output,and electric load at each dispatch time.

The second is the output limit constraint,which ensures that the outputs of the PEM hydrogen production system and PEMFC are within the upper and lower limits at each scheduling time.

(4)Decision variables of lower model

After solving the upper model,the power distribution between PEMEL and BESS was optimized with a 10-min resolution.Therefore,the decision variable of the lower model is the power sequence of PEMEL and BESS ![]() for each period.

for each period.

(5)Objective function lower model

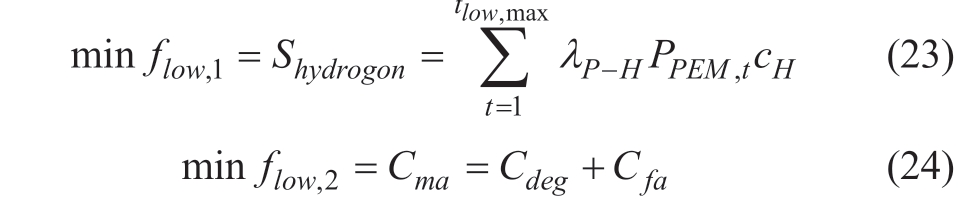

The power allocation of the PEMEL and BESS in a PV hydrogen production system determines its cost.If the PEMEL has a higher PV output value or large PV fluctuation,it will produce more hydrogen;however,there will be severe performance degradation of the electrolyzer,leading to a decrease in efficiency and an increase in equipment maintenance cost.Therefore,measuring the influence of hydrogen production and the degree of attenuation is necessary.The lower-level model had two objective functions.The first objective is to maximize the hydrogen production of the electrolyzer,that is,to maximize the hydrogen production income.The second objective is to minimize the degradation cost caused by the performance attenuation of the PEMEL,that is,to minimize the maintenance cost.

where tlow,max is the maximum time on the low-layer time scale,Shydrogon is the hydrogen production revenue,and the maintenance cost Cma is mainly the degradation cost of the PEMEL and BESS,which are related to their performance attenuation.The remainder is the failure cost related to the capacity and failure probability.

The calculation of the degradation cost of PEMEL was based on the attenuation model proposed in Section 1.2,and different maintenance costs were obtained according to the degradation degree of the materials in various parts of PEMEL.

where k is the cost of PEMEL material replacement and ∆indicates the material degradation value,which includes the membrane,catalyst,and PTL.

(6)Constraint condition of lower model

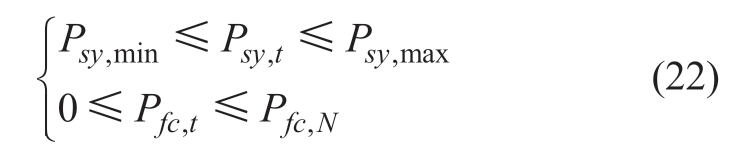

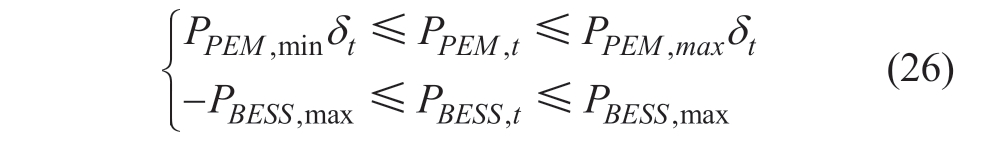

The first constraint is that,at time t,the output values of the BESS and PEMEL are within the rated range.

where PPEM,min is 0.05 NPEM and PPEM,max is 1.5 NPEM,δt is the binary variable indicating the start-stop state of the PEMEL;PBESS,max is the charging and discharging power limit of the BESS,which is proportional to its capacity (0.2,set in this study).

The second constraint condition is that at time t,the sum of the power values of the BESS and PEMEL is equal to the excess PV power absorbed by the hydrogen production system.

The third constraint is the ramp rate limit of the PEMEL;that is,the power change of the PEMEL should be less than the rated value.

where Pr is the ramp rate limit value of PEMEL.

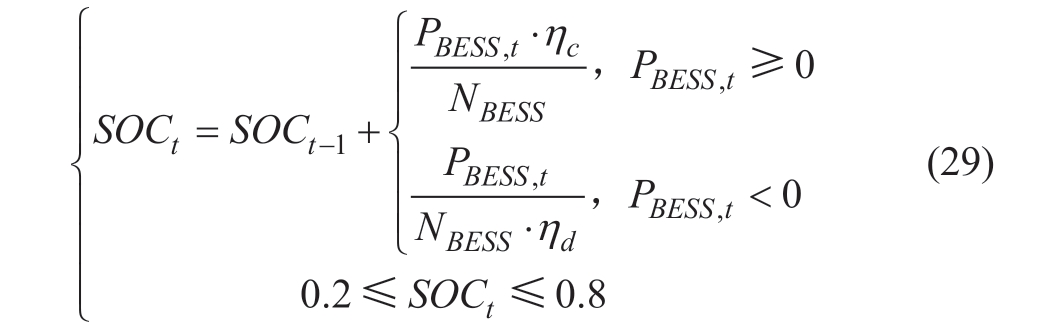

The fourth constraint is the state of charge (SOC)of BESS.The initial SOC to 0.5,and the SOC did not exceed its upper and lower limits.

where ηc(ηd)is the charge (discharge)efficiency.

2.4 Solution of optimization

For up-layer optimization,the main solution is the power that the hydrogen production system should undertake at a 1 h resolution.The YALMIP+Gurobi solver in MATLAB was used to obtain the results.

For low-layer optimization,the main solution is the power distribution of the PEMEL+BESS combination in the hydrogen production system at a 10 min resolution.Because it involves the calculation of the degradation cost caused by the performance attenuation of the PEMEL,the optimization problem is nonlinear and multi-objective.In this study,the improved NSGA-II was used to determine the power distribution,and the optimal Pareto front in the solution set was obtained using the entropy weight method.

The first improvement was the introduction of the FA.The FA has good optimization accuracy;however,it depends on the initial solution and easily falls into a local optimal solution.The basic NSGA-II and FA are introduced in [25];therefore,they will not be expanded in detail in this paper.

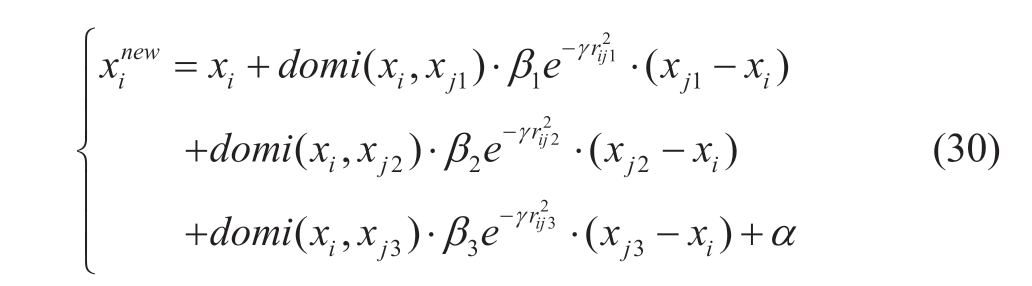

The combination of NSGA-II and FA was used in this study.In the NSGA-II&FA,the attraction of population i to population j needs to form the relationship that i dominates j in brightness comparison.Furthermore,an improved FA method was used in this study.When the firefly searches for a better firefly,three fireflies are selected for evaluation:the better firefly is approached,and the worse firefly is kept away.This achieves the optimal result because firefly i is attracted by three fireflies,and it is not easy to fall into the local optimal solution caused by the attraction of a single firefly.

where x is the firefly;domi a b(,)is the domination function,if a dominates b,the value is 1,if b dominates a,the value is -1;β is the attractiveness;γ is the light absorption coefficient;r is the distance;α is the random parameter.

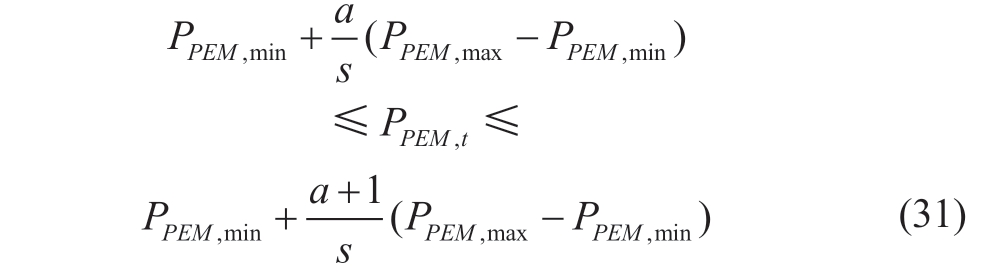

The second improvement was the setting of the power grading.The power of PEMEL was divided into several grades to reduce slight fluctuations caused by the random spatial search.When the population searched for results near the power-grading value,it was set to the grading value.This can improve the unstable results caused by a random population search and reduce the power fluctuation operation of the PEMEL.

where s is the number of power grading,and a is the number between 0 and s-1.

The third improvement was the use of layered scheduling to set the initial population.The layered scheduling method determines the power range of the hydrogen production system through an upper-layer optimization,and the power of the system is passed to the lower layer as the initial solution.This approach not only narrows the lower-layer optimization’s solution variable search space but also enhances search efficiency and lowers the risk of local optima.

The flow chart of layered scheduling optimization is showed in Fig.2.

Fig.2 The flow chart of optimization

3 Example analysis

3.1 Data and parameters

Data from a PV plant in northwest China were used in this study.Typical PV power curves were obtained by clustering,and the scene probability ratios q of the curves were counted.The clustering method in this study extracts the fluctuation and level of the PV power,simplifies the PV power curves into a characteristic array,and finally clusters the characteristic array to obtain typical PV power curves with different fluctuation levels.

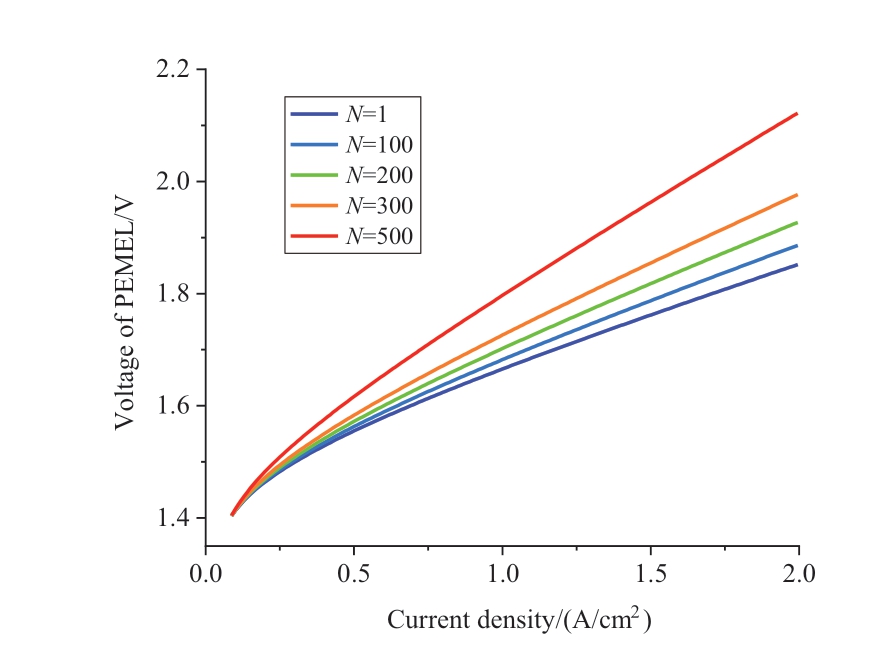

To verify the feasibility of the proposed attenuation model,we constructed an attenuation model for PEMEL using MATLAB/Simulink.Typical PV power curves were input,and the degradation results are shown in Fig.3.It was confirmed that the model can describe the degradation of the PEMEL under a fluctuating power input.

Fig.3 The polarization curve of PEMEL model in different cycle numbers (N)of PV power input

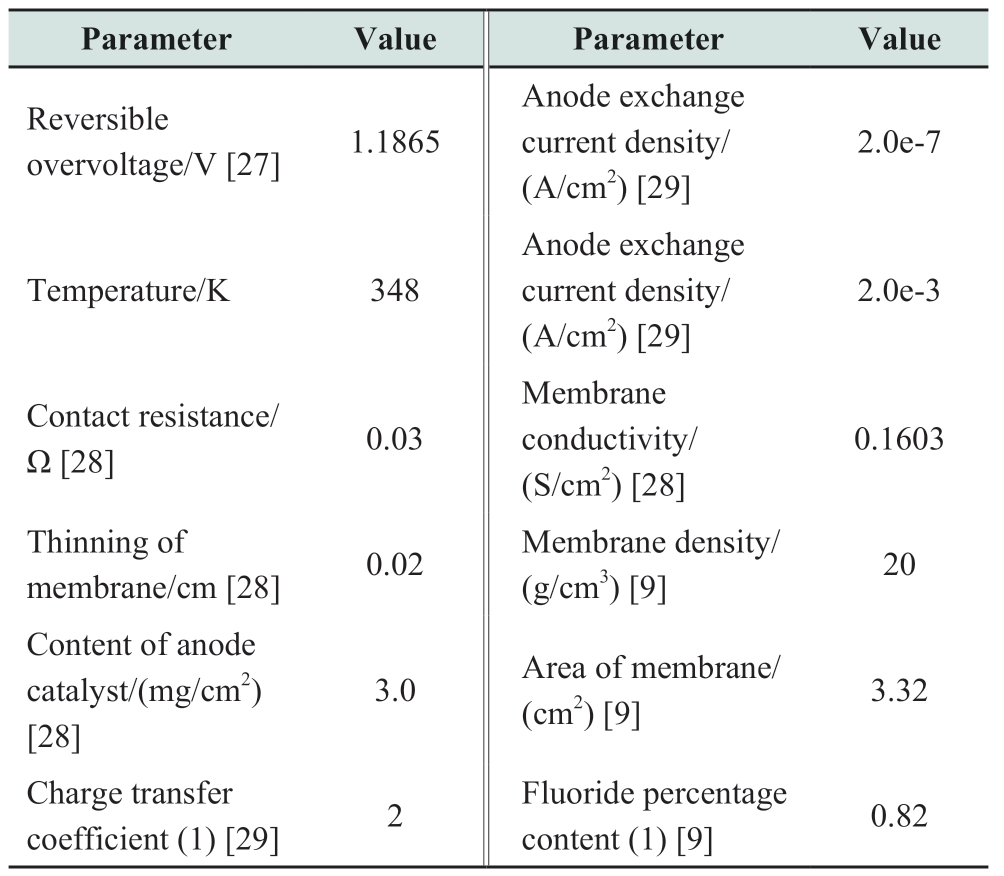

The parameter values of the PEMEL model are listed in Table 1,and those of the life-cycle cost of the hydrogen production system are listed in Table 2.

Table 1 The parameter values of PEMEL model

Table 2 The parameter values of life cycle costs

3.2 Optimization result

The PV power hydrogen production system must be consumed by substituting the four types of typical PV curve data into the upper optimization model.Because the main target of a hydrogen production system is to absorb surplus PV resources,the optimization time of this study was set to 10 h within a typical day (i.e.,8:00 to 18:00),during which PV resources are the most abundant.

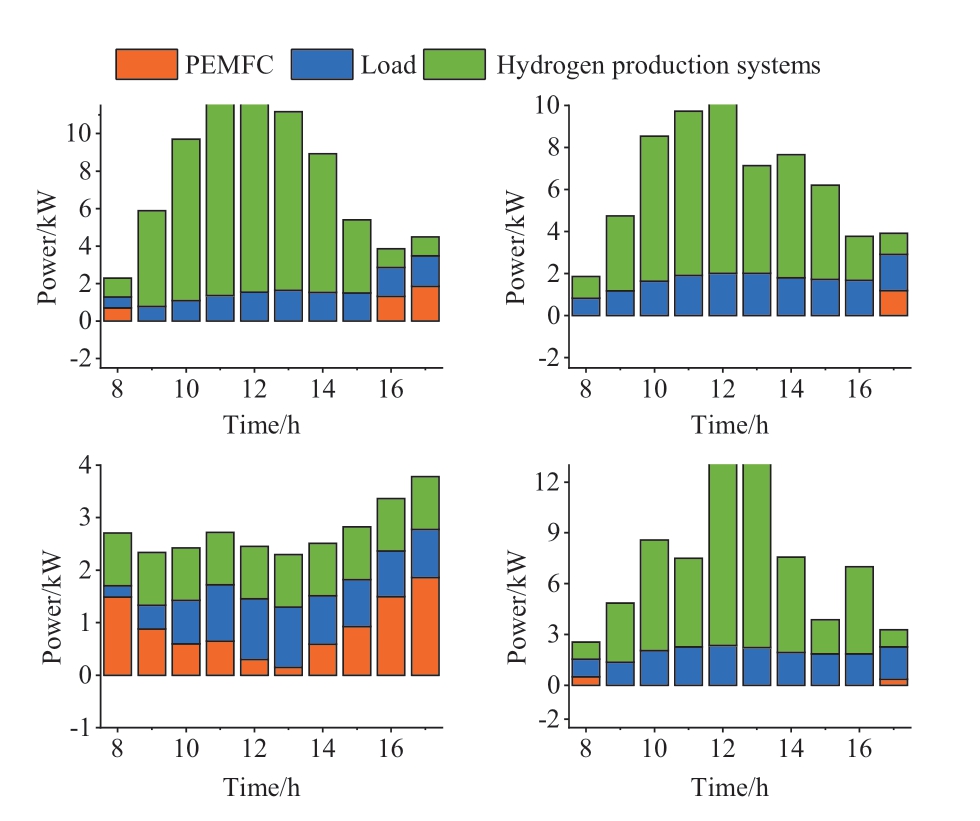

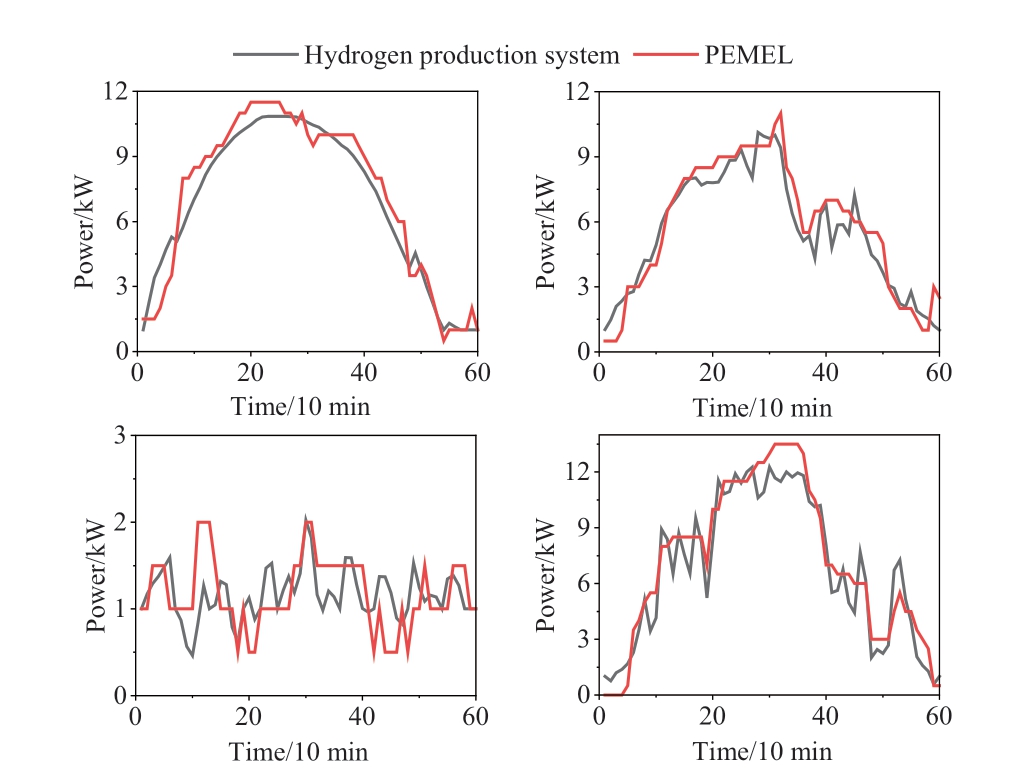

From the up-layer optimization results shown in Fig.4,most of the PV power is absorbed by the hydrogen production system.If the PV power output is too low,the PEMFC supports the system to maintain the lowest power of the hydrogen production system.

Fig.4 Up-layer optimization result of PEMEL in four typical days

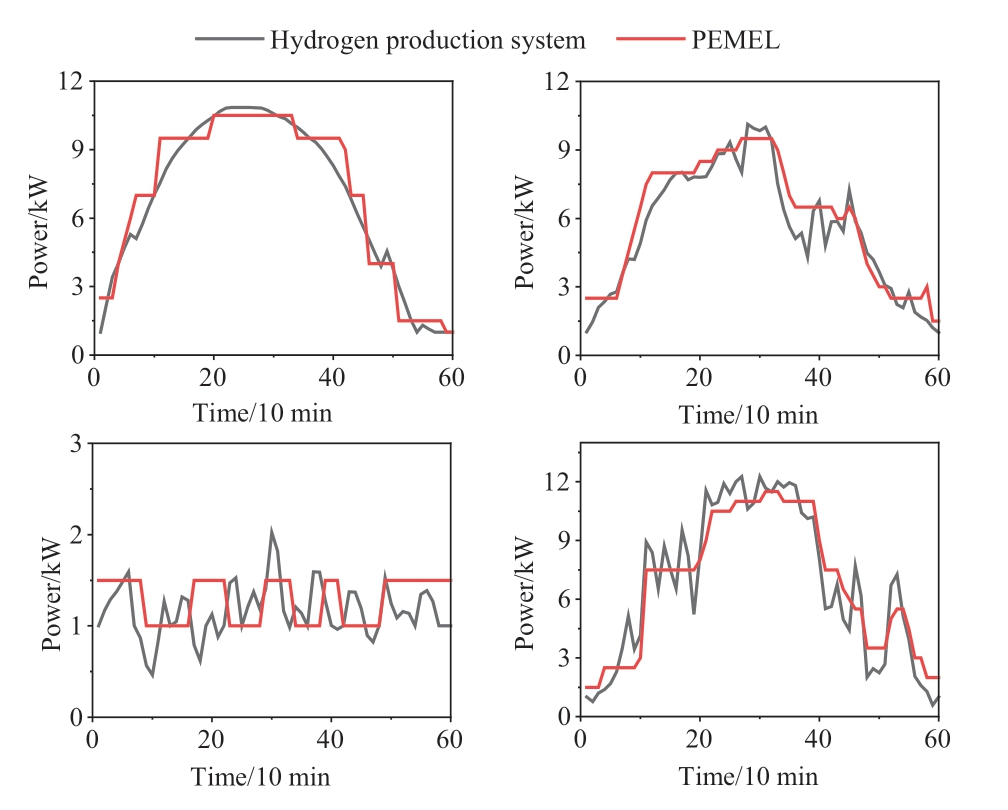

Fig.5 Low-layer optimization result of PEMEL in four typical days

From the low-layer optimization results in Fig.5,compared with the PV power,the hydrogen production system absorbs,and the working power of the PEMEL has a larger output value in the low-power region and a smaller output value in the high-power region.The result of this optimization can produce more hydrogen in the low-power region,avoiding overload in the high-power region and reducing the overall fluctuation of the power curve.The optimized working power of the PEMEL stabilizes frequentfluctuation PV power,which can significantly reduce the degradation cost.

3.3 Contrastive analysis

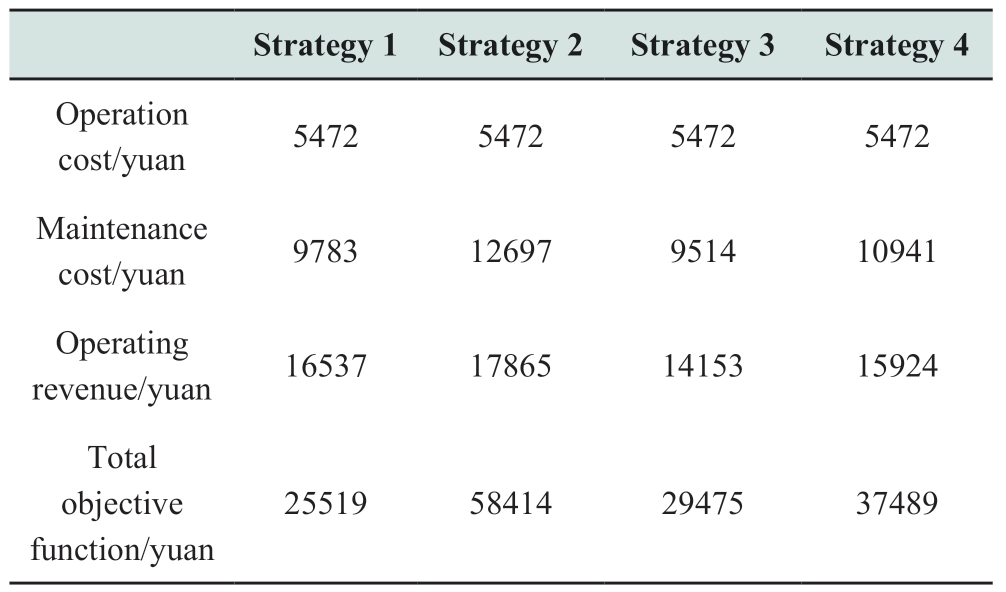

The optimization strategy in this study was set as Strategy 1,the optimization strategy considering only the revenue from hydrogen production was set as Strategy 2,and the optimization strategy considering only the performance attenuation of the PEMEL was set as Strategy 3.The optimization strategy in which only PEMEL participates in the consumption of PV resources was set as Strategy 4.The results of power scheduling optimization under the four strategies are analyzed below.

The O&M costs,operating income,and total objective function values obtained using the four strategies are listed in Table 3.The power-scheduling optimization result of Strategy 2 has the largest operating revenue because this strategy has the largest hydrogen production.However,PEMEL bears all these fluctuations,leading to an increased degradation cost.The power scheduling optimization result of Strategy 3 has the minimum maintenance cost because this strategy has the minimum performance attenuation of the PEMEL,and the degradation cost of the component materials is lower in the system life cycle.However,the minimal performance attenuation is always accompanied by low hydrogen production.

Strategy 1 considered hydrogen production revenue and PEMEL performance attenuation.The entropy weight method was used to select the optimal Pareto solution in the multi-objective optimization and find the best combination of operating revenue and maintenance costs.The total objective function value of Strategy 1 is less than those of Strategies 2 and 3,proving the advantage of multi-objective optimization.

For Strategy 4,when the BESS is not installed,the investment cost of equipment is greatly reduced compared with other strategies;therefore,it has a smaller total objective function value.However,compared with Strategy 1 proposed in this study,the power distribution of the electrolyzer is not reasonable without a BESS,and the input power is in the range of low hydrogen production efficiency,which makes the total hydrogen production revenue slightly lower.In addition,without a BESS to suppress power fluctuations,the performance of the PEMEL is more seriously attenuated,and the maintenance cost is higher.Given the current high replacement cost of PEMEL,employing a BESS to stabilize input power fluctuations is still necessary.It is hoped that in the future,the cost of PEMEL will be greatly reduced,and the performance attenuation under fluctuation will be slowed down so that we do not need to be equipped with a battery energy storage system.

Table 3 Optimization results of different strategies

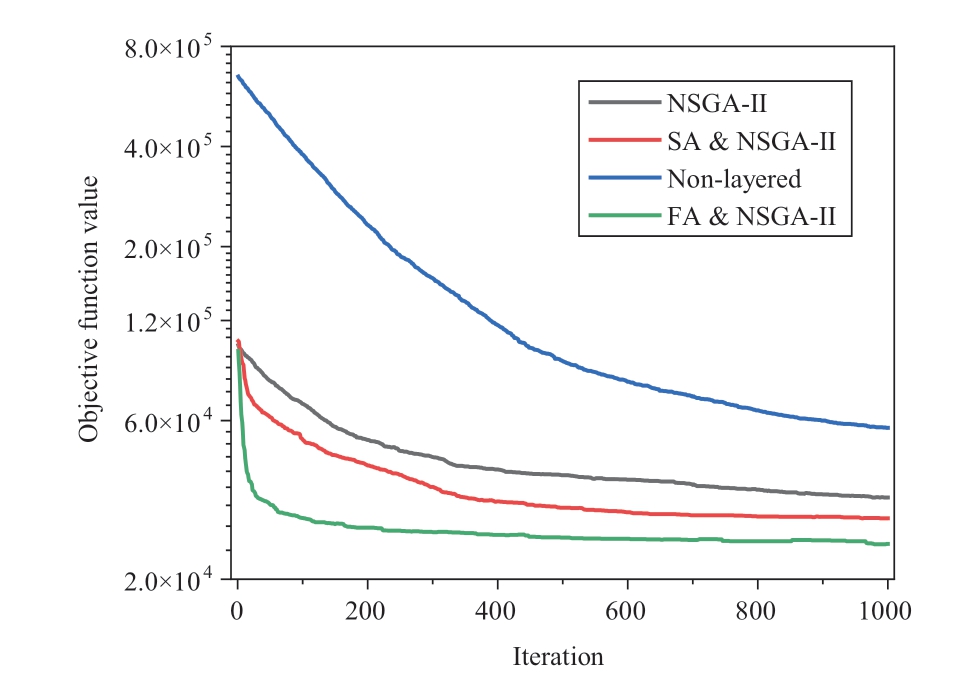

To prove the effectiveness of the improved layered scheduling optimization method proposed in this study,three groups of comparisons were established.In the first group,the global NSGA-II search for the power of PEMEL was directly performed without layered scheduling.The second group adopted layered scheduling but did not adopt the improved NSGA-II search algorithm.The third group is the improved GA,SA&GA,which is commonly used in search optimization.Fig.6 shows the objective function values of the optimization results obtained in each generation when the total number of iterations was N=1000.It can be observed that the objective function value of the initial population is significantly large without layered scheduling optimization,and the larger search space and poorer local search ability of the NSGA-II search algorithm require more iterations to obtain better results.Using layered scheduling optimization,the search space of lower-layer decision variables can be constrained to a certain range,the search time can be significantly reduced,and the objective function value obtained under the same iteration is better.In addition,compared with SA and NSGA-II,the improved FA and NSGA-II algorithms proposed in this study improve the search ability,which can search for a lower objective function value with fewer iterations.

Fig.6 The objective function value of different search methods

3.4 Sensitivity analysis

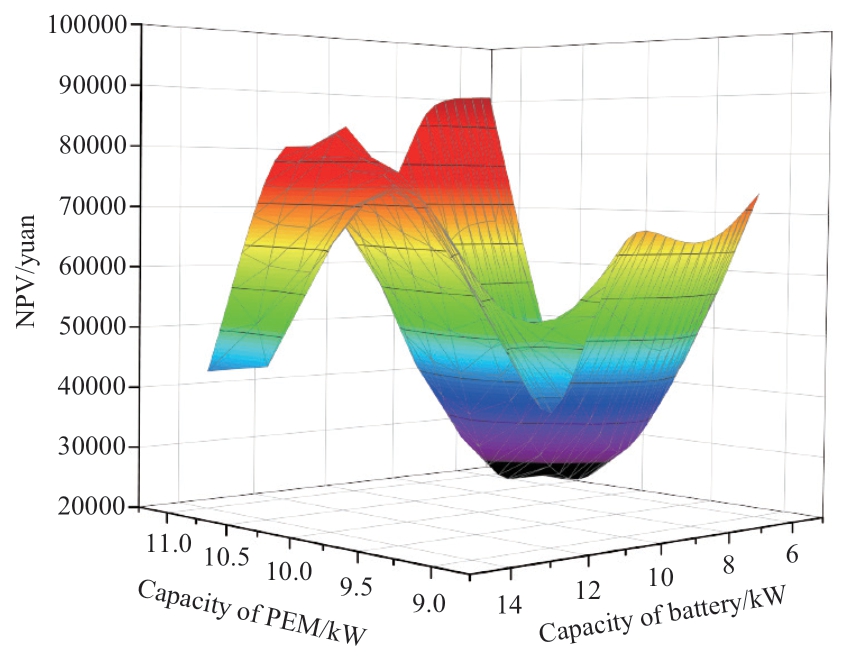

For the different capacities of the PEMEL in the PV hydrogen production system,the NPV in the entire life cycle under each typical daily PV input was compared.

From Fig.7,the optimal capacity configuration is such that the rated capacity of the PEMEL is 10 kW,and the rated capacity of the BESS is 10 kW.If the capacity is too large,the investment cost will take a significant part of the life cycle cost,and if the capacity is too small,the hydrogen production would be reduced,and the ability to suppress the PV fluctuation of the BESS will weaken.Under a reasonable capacity-sizing configuration,the minimum LCC of the system can be achieved.

Fig.7 NPV of PV hydrogen production system in different capacities

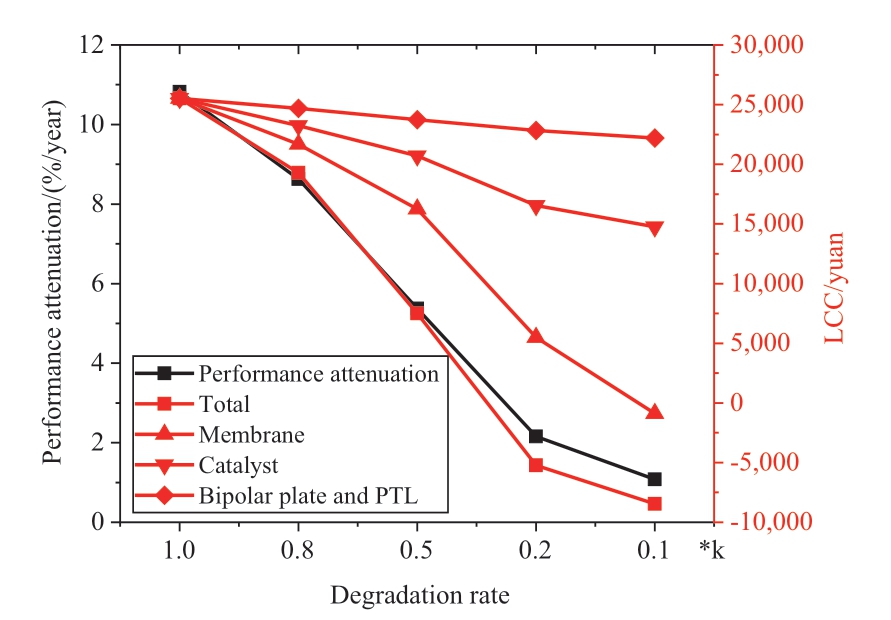

Then,the degradation rates of the material components in (9),(12),and (14)are compared to the LCC,that is,the total objective function.Fig.8 shows the results of the LCC at different degradation rates,where k is the initial degradation rate,and the variation of the abscissa indicates the linear adjustment of the degradation rate.It was found that a reduction in the degradation rate of the components will slow down the voltage degradation rate of the PEMEL and reduce the maintenance cost.When the total degradation rate reaches approximately 0.2 times the initial value,the total objective function value changes from positive to negative,indicating that the entire system turns from loss to profit in the entire life cycle.In addition,when the total degradation rate is lower than 0.1 times of the initial value,the scheduling optimization result does not consider the degradation cost caused by the performance attenuation of the PEMEL under fluctuating input and mainly considers maximizing the hydrogen production;therefore,the power of the PEMEL tends to be higher than that of the PV power hydrogen production system.

Fig.9 shows that if the material cost of PEMEL is sufficiently low,the investment and operation costs of the BESS will be greater than the degradation cost of the PEMEL equipped with it,indicating that energy storage equipment is not needed in the case of a low degradation cost of the electrolyzer.

Fig.8 Performance attenuation and NPV of PV hydrogen production system in different degradation rates

Fig.9 Low-layer optimization result of PEMEL when degradation rate is 0.1 times the initial value

This research shows that if the degradation mechanism of PEMEL components can be studied and treatment methods to delay the degradation can be provided,the adaptability and system economy of hydrogen production in an environment of highly fluctuating renewable energy input can be greatly improved.

4 Conclusion

In a PV hydrogen production system equipped with a BESS to manage fluctuations,this study proposes an optimization method for power scheduling that considers both hydrogen production and performance attenuation.The main conclusions are as follows:

1)A performance attenuation function for PEMEL was proposed.Performance attenuation phenomena,such as membrane thinning,dissolution and shedding of the anode catalyst,and passivation of the porous transport layer,are expressed as functions of the input power.Based on the construction of the MATLAB/Simulink model,it was verified that the model could describe the performance attenuation characteristics under a fluctuating input.

2)Compared with other power scheduling optimization methods,the method proposed in this study can weigh the hydrogen production benefit and performance attenuation of PEMEL and obtain the most economical power scheduling for the entire hydrogen production system.In the strategy proposed in this study,the maintenance cost is 9783 yuan,the operating revenue is 16537 yuan,and the objective function is 25519 yuan,which are lower than those of the other strategies.

3)The improved optimization algorithm proposed in this study has a better ability to search for a lower objective function.Layered scheduling optimization has a lower objective function in the initial iteration.Compared with NSGA-II and SA &NSGA-II,the proposed FA &NSGA-II converged to the optimal solution in 300 iterations,and the convergent objective function was lower.

4)Through sensitivity analysis,this study highlights the influence of the component application and degradation mechanism of PEMEL on the cost of the hydrogen production system.When the degradation rate is 0.5 times lower than the original rate,the LCC changes from positive to negative,showing that the system can run profitably.It is expected that the improvement in PEMEL technology in the future can fully adapt to PV input under extreme fluctuations.

Because there is no detailed attenuation function of PEMEL in existing research,the optimization method of power scheduling proposed in this study is a simple attenuation function based on experimental results,which makes it difficult to accurately express the complex relationship between PEMEL performance attenuation and input power.If a more accurate performance attenuation relationship can be obtained,the optimization result will be more accurate,requiring further analysis of the internal operation mechanism of the PEMEL.In future work,a more accurate degradation model of PEMEL will be required,and more cases of PEMEL applications will be researched.

Acknowledgements

This study was supported by the National Key Research and Development Program of China (Materials and Process Basis of Electrolytic Hydrogen Production from Fluctuating Power Sources such as Photovoltaic/Wind Power,No.2021YFB4000100).

Declaration of Competing Interest

We declare that we have no conflict of interest.

References

[1] Li J,Li G,Liang D,et al.(2021)Review and prospect of hydrogen production technology from renewable energy under targets of carbon peak and carbon neutrality.Distributed Energy,6(5):1-9

[2] Ge L,Cui Q,Li M,et al.(2022)Review on water electrolysis for hydrogen production powered by fluctuating wind power and PV.Integrated Intelligent Energy,44(5):1-14

[3] Bodkhe R G,Shrivastava R L,Soni V K,et al.(2023)A review of renewable hydrogen generation and proton exchange membrane fuel cell technology for sustainable energy development.International Journal of Electrochemical Science,18(5).doi:ARTN 10010810.1016/j.ijoes.2023.100108

[4] Ma X,Zhang S,He Y,et al.(2022)Research status and application prospect of PEM electrolysis water technology for hydrogen production.Acta Energiae Solaris Sinica,43(6):420-427

[5] Ji Q,Xu Q,Yu H,et al.(2020)Status and trend of hydrogen production technologies through water electrolysis by proton exchange membrane.Modern Chemical Industry,41(4):72-76+81

[6] Zhang H,Yuan T (2022)Optimization and economic evaluation of a PEM electrolysis system considering its degradation in variable-power operations.Applied Energy,324.doi:ARTN 11976010.1016/j.apenergy.2022.119760

[7] Aki H,Sugimoto I,Sugai T,et al.(2018)Optimal operation of a photovoltaic generation-powered hydrogen production system at a hydrogen refueling station.International Journal of Hydrogen Energy,43(32):14892-14904

[8] Fang R M,Liang Y (2019)Control strategy of electrolyzer in a wind-hydrogen system considering the constraints of switching times.International Journal of Hydrogen Energy,44(36):25104-25111

[9] Jiang Y,Yang G,Chen Y,et al.(2023)Optimal operation for the hydrogen network under consideration of the dynamic hydrogen production efficiency of electrolyzers.Proceedings of the CSEE,43(8):3014-3027

[10] Song Y,Mu H,Li N,et al.(2023)Multi-objective optimization of large-scale grid-connected photovoltaic-hydrogen-natural gas integrated energy power station based on carbon emission priority.International Journal of Hydrogen Energy,48(10):4087-4103

[11] Khatib F N,Wilberforce T,Ijaodola O,et al.(2019)Material degradation of components in polymer electrolyte membrane (PEM)electrolytic cell and mitigation mechanisms:A review.Renewable &Sustainable Energy Reviews,111:1-14

[12] Frensch S H,Fouda-Onana F,Serre G,et al.(2019)Influence of the operation mode on PEM water electrolysis degradation.International Journal of Hydrogen Energy,44(57):29889-29898

[13] Kojima H,Nagasawa K,Todoroki N,et al.(2023)Influence of renewable energy power fluctuations on water electrolysis for green hydrogen production.International Journal of Hydrogen Energy,48(12):4572-4593

[14] Siracusano S,Trocino S,Briguglio N,et al.(2020)Analysis of performance degradation during steady-state and load-thermal cycles of proton exchange membrane water electrolysis cells.Journal of Power Sources,468.doi:ARTN 22839010.1016/j.jpowsour.2020.228390

[15] Grigoriev S A,Dzhus K A,Bessarabov D G,et al.(2014)Failure of PEM water electrolysis cells:Case study involving anode dissolution and membrane thinning.International Journal of Hydrogen Energy,39(35):20440-20446

[16] Chandesris M,Medeau V,Guillet N,et al.(2015)Membrane degradation in PEM water electrolyzer:Numerical modeling and experimental evidence of the influence of temperature and current density.International Journal of Hydrogen Energy,40(3):1353-1366

[17] Kang Z,Wang H,Liu Y,et al.(2022)Exploring and understanding the internal voltage losses through catalyst layers in proton exchange membrane water electrolysis devices.Applied Energy,317.doi:ARTN 11921310.1016/j.apenergy.2022.119213

[18] Alia S M,Stariha S,Borup R L (2019)Electrolyzer durability at low catalyst loading and with dynamic operation.Journal of the Electrochemical Society,166(15):F1164-F1172

[19] Zheng Y,Jiao Y,Jaroniec M,et al.(2015)Advancing the electrochemistry of the hydrogen-evolution reaction through combining experiment and theory.Angewandte Chemie-International Edition,54(1):52-65

[20] Rakousky C,Reimer U,Wippermann K,et al.(2016)An analysis of degradation phenomena in polymer electrolyte membrane water electrolysis.Journal of Power Sources,326:120-128

[21] Bystron T,Veselý M,Paidar M,et al.(2018)Enhancing PEM water electrolysis efficiency by reducing the extent of Ti gas diffusion layer passivation.Journal of Applied Electrochemistry,48.doi:10.1007/s10800-018-1174-6

[22] Liu C,Carmo M,Bender G,et al.(2018)Performance enhancement of PEM electrolyzers through iridium-coated titanium porous transport layers.Electrochemistry Communications,97:96-99

[23] Yue M,Li Z,Roche R,et al.(2022)Degradation identification and prognostics of proton exchange membrane fuel cell under dynamic load.Control Engineering Practice,118.doi:10.1016/j.conengprac.2021.104959

[24] Moein-Jahromi M,Kermani M J,Movahed S (2017)Degradation forecast for PEMFC cathode-catalysts under cyclic loads.Journal of Power Sources,359:611-625.doi:10.1016/j.jpowsour.2017.05.102

[25] Kim J,Lee J,Cho B H (2013)Equivalent circuit modeling of PEM fuel cell degradation combined with a LFRC.Ieee Transactions on Industrial Electronics,60(11):5086-5094.doi:10.1109/tie.2012.2226414

[26] Luxa A,Jores N,Yanez C C,et al.(2022)Multilinear modeling and simulation of a multi-stack PEM electrolyzer with degradation for control concept comparison.Paper presented at the 12th International Conference on Simulation and Modeling Methodologies,Technologies and Applications (SIMULTECH),Lisbon,PORTUGAL

[27] Schalenbach,M,Tjarks,G,Carmo,M,et al.(2016)Acidic or alkaline? Towards a new perspective on the efficiency of water electrolysis.Journal of The Electrochemical Society,163(11):F3197-F3208

[28] Koponen J,Ruuskanen V,Hehemann M,et al.(2020)Effect of power quality on the design of proton exchange membrane water electrolysis systems.Applied Energy,279.doi:10.1016/j.apenergy.2020.115791

[29] Yigit T,Selamet O F (2016)Mathematical modeling and dynamic Simulink simulation of high-pressure PEM electrolyzer system.International Journal of Hydrogen Energy,41(32):13901-13914

[30] Bernhard D,Kadyk T,Kirsch S,et al.(2023)Model-assisted analysis and prediction of activity degradation in PEM-fuel cell cathodes.Journal of Power Sources,562.doi:ARTN 23277110.1016/j.jpowsour.2023.232771

[31] Fouda-Onana F,Chandesris M,Medeau V,et al.(2016)Investigation on the degradation of MEAs for PEM water electrolysers part I:Effects of testing conditions on MEA performances and membrane properties.International Journal of Hydrogen Energy,41(38):16627-16636

[32] Motaghedi-Larijani A (2022)Solving the number of crossdock open doors optimization problem by combination of NSGA-II and multi-objective simulated annealing.Applied Soft Computing,128:109448

[33] Lei Z,Wang C,Dong Y,et al.(2022)On scheduling optimization of new energy based hydrogen production using improved seagull algorithm.Modern Electric Power,39(5):514-520

[34] Hou R,Maleki A,Li P (2022)Design optimization and optimal power management of standalone solar-hydrogen system using a new metaheuristic algorithm.Journal of Energy Storage,55.doi:10.1016/j.est.2022.105521

[35] IRENA (2020)Green hydrogen cost reduction:Scaling up electrolysers to meet the 1.5 ℃ climate goal.International Renewable Energy Agency,Abu Dhabi

Scan for more details

Received:17 July 2023/Revised:13 September 2023/

Accepted:13October 2023/Published:25 December 2023

Yanhui Xu

Yanhui Xu

xuyanhui23@sohu.com

Haowei Chen

chw1999827@163.com

2096-5117/© 2023 Global Energy Interconnection Development and Cooperation Organization.Production and hosting by Elsevier B.V.on behalf of KeAi Communications Co.,Ltd.This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Biographies

Yanhui Xu received the Ph.D.degree at North China Electricity Power University,Beijing,China,2010.He is working at North China Electricity Power University,Beijing,China.His research interests include dynamic power systems analysis and load modeling.

Haowei Chen is working towards a master’s degree at North China Electricity Power University,Beijing,China.His research interests include technologies for hydrogen production by electrolysis of renewable energy.

(Editor Yajun Zou)