1 Introduction

China contains abundant hydropower resources due to its vast territory,many rivers,rich runoff and fall head.The installed capacity for possible technical development is about 687 million kW,and it thus ranks first in the world.Such hydropower resources are mainly concentrated around the transboundary rivers of southwest China:the Jinsha River,the Yalong River,the Dadu River,the Wujiang River,the upper reaches of the Yangtze River,the Nanpan River-Hongshui River,the upper reaches of the Yellow River,the middle reaches of the Yellow River,and other main basins and regions in western Hunan Province.Hydropower resources are also concentrated in the Fujian-Zhejiang-Jiangxi provinces,northeast China,where fourteen large hydropower bases have been planned,with a total installed capacity accounting for about 50% of possible technical exploitation amount nationwide.

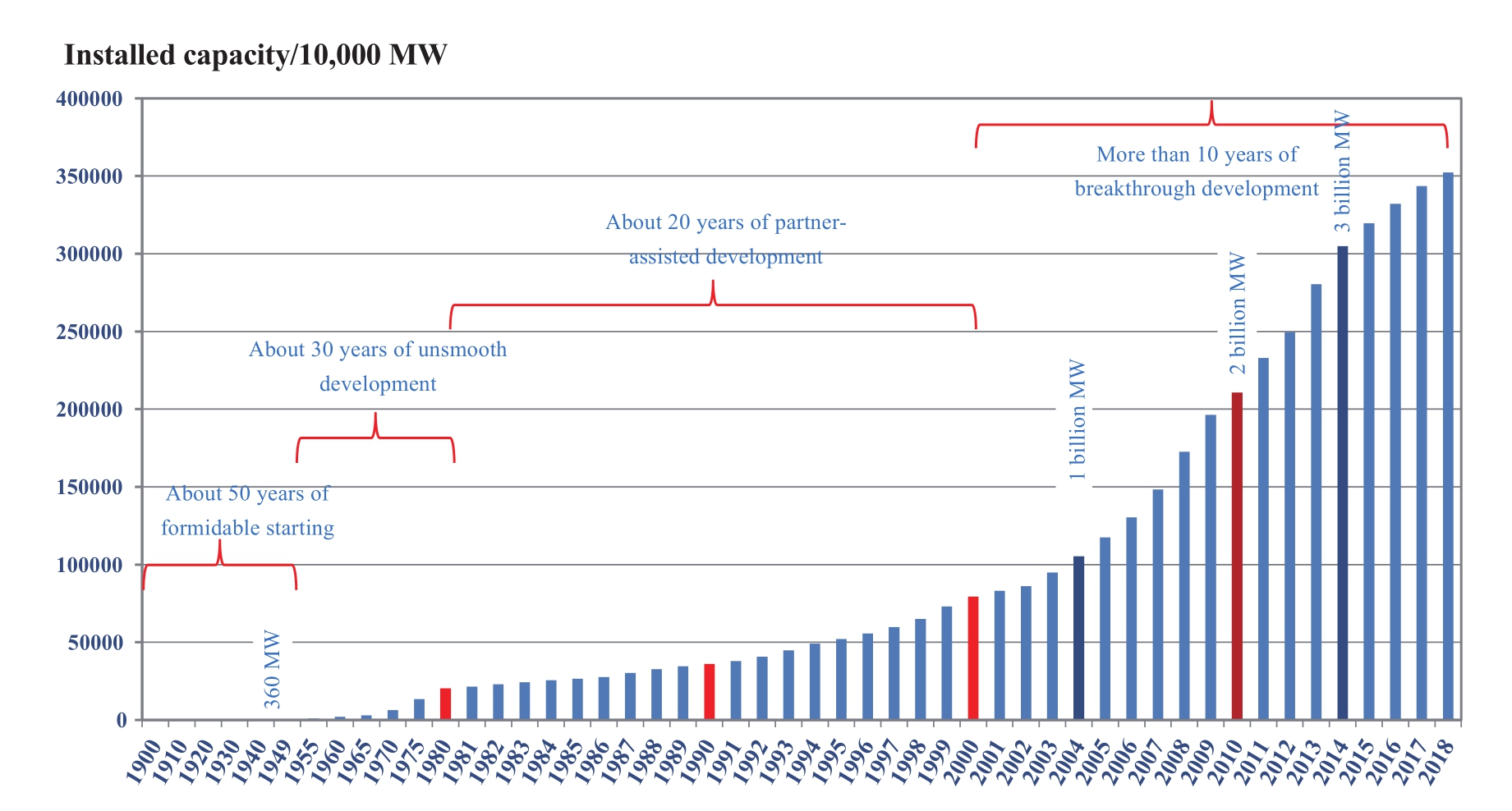

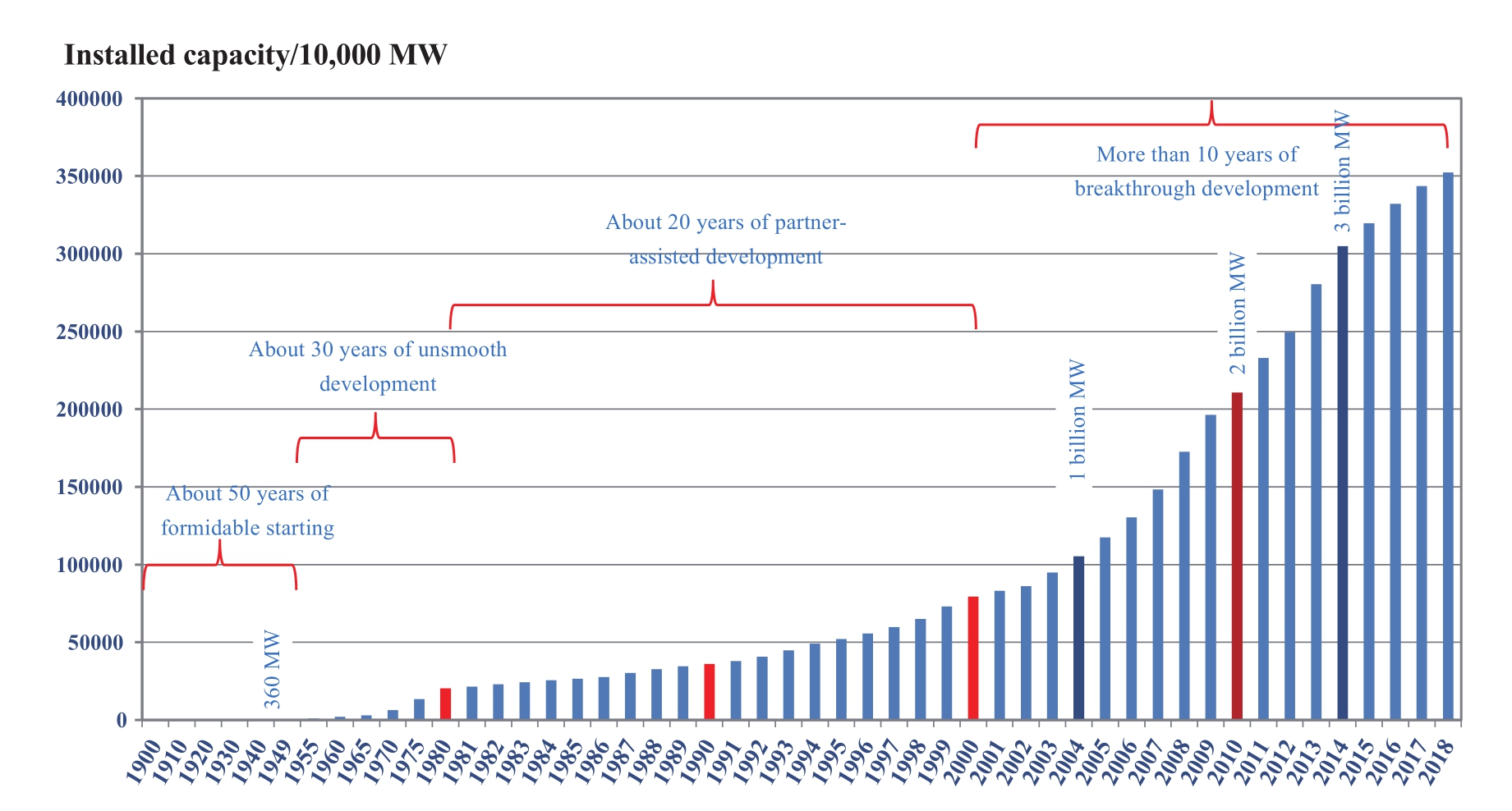

From the beginning of the last century,the history of China’s hydropower development can be roughly divided into the following major stages:formidable starting point(1900-1949),unsmooth development (1950-1979),partnerassisted development (1980-1999),and breakthrough development (2000-2018) (Fig.1).Over a period spanning from the beginning of the Western Regions Development

Fig.1 Developmental trends with regard to China's hydropower installed capacity

Strategy (1999) and the West-East Power Transmission Project’s implementation till the end of 2018,the total installed capacity of hydropower reached 352.26 million MW (including about 30,000 MW for that of pumped storage),accounting for 18.5% of the total installed capacity nationwide; furthermore,annual hydroelectric generation has reached 1,232.9 billion kWh,accounting for 17.6%of electricity generation nationwide.Thus,China’s hydropower installed capacity and generation rank first in the world.With key projects planned on the Jinsha River,the Dadu River,and other rivers,which are supported by the 13th Five-year Plan,at present,the conventional hydropower installed capacity under construction is about 510 million MW.China has achieved comprehensive leap-over in terms of installed capacity and hydroelectric generation,design and construction,equipment manufacturing,and operational management.

The breakthrough developments in hydropower generation have expedited huge hydropower station projects in China.The number of as-built hydropower station projects with an installed capacity exceeding 3,000 MW reached 13 by the end of 2018 (Table1).These large-capacity projects,which utilize hydropower engineering technologies at the world’s highest level,have accordingly accumulated abundant experience and made a series of innovation achievements with regard to construction technologies for 300-meter-high arched concrete dams,200-meter-high roller-compacted concrete(RCC) gravity dams,200-meter-high concrete face rockfill dams and 250-meter-high earth core rockfill dams,largeflow discharge and energy dissipation,huge underground cavern group construction projects,complicated treatments for the foundations of high earth and rockfill dams,and reinforcements for high and steep slopes.

Table1 China's as-built hydropower station projects with an installed capacity of over 3,000 MW

continue

Note:1.Total capacity of the reservoir in the table refers to the capacity below the check flood level; 2.There are statistical differences between different data resources.

China’s hydropower engineering construction projects have experienced rapid development and made several brilliant achievements.The Jinping-I Hydropower Station won the Hassib J.Sabbagh Outstanding Engineering Construction Prize of the World Federation of Engineering Organizations (WFEO),the Xiluodu Hydropower Station won the FIDIC Century Outstanding Significant Civil Engineering Prize,the Nuozhadu Hydropower Station won the FIDIC excellent engineering project prize; furthermore,the Ertan,Shuibuya,Nuozhadu,and Jinping-I hydropower stations along with several others won significant prizes such as the National Prize for Progress in Science and Technology,the High Quality Engineering Award,the Luban Prize,the Excellent Design Engineering award,the Tien-yow Jeme Civil Engineering Prize,the International Milestone Concrete Dam Project designation,and the International Milestone Rockfill Dam Project designation.

China contains abundant hydropower resources due to its vast territory,many rivers,rich runoff and fall head.The installed capacity for possible technical development is about 687 million kW,and it thus ranks first in the world.Such hydropower resources are mainly concentrated around the transboundary rivers of southwest China:the Jinsha River,the Yalong River,the Dadu River,the Wujiang River,the upper reaches of the Yangtze River,the Nanpan River-Hongshui River,the upper reaches of the Yellow River,the middle reaches of the Yellow River,and other main basins and regions in western Hunan Province.Hydropower resources are also concentrated in the Fujian-Zhejiang-Jiangxi provinces,northeast China,where fourteen large hydropower bases have been planned,with a total installed capacity accounting for about 50% of possible technical exploitation amount nationwide.

From the beginning of the last century,the history of China’s hydropower development can be roughly divided into the following major stages:formidable starting point(1900-1949),unsmooth development (1950-1979),partnerassisted development (1980-1999),and breakthrough development (2000-2018) (Fig.1).Over a period spanning from the beginning of the Western Regions Development

Fig.1 Developmental trends with regard to China's hydropower installed capacity

Strategy (1999) and the West-East Power Transmission Project’s implementation till the end of 2018,the total installed capacity of hydropower reached 352.26 million MW (including about 30,000 MW for that of pumped storage),accounting for 18.5% of the total installed capacity nationwide; furthermore,annual hydroelectric generation has reached 1,232.9 billion kWh,accounting for 17.6%of electricity generation nationwide.Thus,China’s hydropower installed capacity and generation rank first in the world.With key projects planned on the Jinsha River,the Dadu River,and other rivers,which are supported by the 13th Five-year Plan,at present,the conventional hydropower installed capacity under construction is about 510 million MW.China has achieved comprehensive leap-over in terms of installed capacity and hydroelectric generation,design and construction,equipment manufacturing,and operational management.

The breakthrough developments in hydropower generation have expedited huge hydropower station projects in China.The number of as-built hydropower station projects with an installed capacity exceeding 3,000 MW reached 13 by the end of 2018 (Table1).These large-capacity projects,which utilize hydropower engineering technologies at the world’s highest level,have accordingly accumulated abundant experience and made a series of innovation achievements with regard to construction technologies for 300-meter-high arched concrete dams,200-meter-high roller-compacted concrete(RCC) gravity dams,200-meter-high concrete face rockfill dams and 250-meter-high earth core rockfill dams,largeflow discharge and energy dissipation,huge underground cavern group construction projects,complicated treatments for the foundations of high earth and rockfill dams,and reinforcements for high and steep slopes.

Table1 China's as-built hydropower station projects with an installed capacity of over 3,000 MW

continue

Note:1.Total capacity of the reservoir in the table refers to the capacity below the check flood level; 2.There are statistical differences between different data resources.

China’s hydropower engineering construction projects have experienced rapid development and made several brilliant achievements.The Jinping-I Hydropower Station won the Hassib J.Sabbagh Outstanding Engineering Construction Prize of the World Federation of Engineering Organizations (WFEO),the Xiluodu Hydropower Station won the FIDIC Century Outstanding Significant Civil Engineering Prize,the Nuozhadu Hydropower Station won the FIDIC excellent engineering project prize; furthermore,the Ertan,Shuibuya,Nuozhadu,and Jinping-I hydropower stations along with several others won significant prizes such as the National Prize for Progress in Science and Technology,the High Quality Engineering Award,the Luban Prize,the Excellent Design Engineering award,the Tien-yow Jeme Civil Engineering Prize,the International Milestone Concrete Dam Project designation,and the International Milestone Rockfill Dam Project designation.

2 Leading-edge technologies

2.1 A series of technologies for constructing 300-meter-high concrete arch dams

China’s development of arch dam construction technology began relatively early,with the building of seven extra-high double-curvature arch dams that exceeded 200 m; these included the Ertan,Xiaowan,Jinping-I,and Xiluodu dams and several others.(Table2) Among them,the Jinping-I Arch Dam,the world’s highest as-built dam,reaches a maximum height of 305 m,and the Xiaowan Arch Dam has a body volume of almost 8 million m3 with a maximum base width of 73 m.The constructions of these extra-high double-curvature arch dams are often faced with engineering technology challenges such as complicated geological conditions,requirements for large quantities of foundation and slope treatments,the huge hydraulic thrusts against dams,high stress levels for the body,serious abutment stability problems,complicated anti-seismic problems,and large body volumes; thus,they impose very high requirements in terms of dam design and construction technique.

Chinese engineers have conducted a lot of work in the areas of reconnaissance,design,calculation,testing,and construction study with regard to these extra-high doublecurvature arch dams; they have thus developed various technologies such as static and dynamic safety evaluation,static and dynamic analysis models for system simulation,anti-seismic designs and construction techniques,temperature control and crack prevention for mass concrete structures,intelligent construction theory and system development,concrete construction techniques relying mainly on cable crane placing and grouting treatments for complicated dam foundations.

Table2 China's as-built 200 m above double-curvature arch dams

China’s development of arch dam construction technology began relatively early,with the building of seven extra-high double-curvature arch dams that exceeded 200 m; these included the Ertan,Xiaowan,Jinping-I,and Xiluodu dams and several others.(Table2) Among them,the Jinping-I Arch Dam,the world’s highest as-built dam,reaches a maximum height of 305 m,and the Xiaowan Arch Dam has a body volume of almost 8 million m3 with a maximum base width of 73 m.The constructions of these extra-high double-curvature arch dams are often faced with engineering technology challenges such as complicated geological conditions,requirements for large quantities of foundation and slope treatments,the huge hydraulic thrusts against dams,high stress levels for the body,serious abutment stability problems,complicated anti-seismic problems,and large body volumes; thus,they impose very high requirements in terms of dam design and construction technique.

Chinese engineers have conducted a lot of work in the areas of reconnaissance,design,calculation,testing,and construction study with regard to these extra-high doublecurvature arch dams; they have thus developed various technologies such as static and dynamic safety evaluation,static and dynamic analysis models for system simulation,anti-seismic designs and construction techniques,temperature control and crack prevention for mass concrete structures,intelligent construction theory and system development,concrete construction techniques relying mainly on cable crane placing and grouting treatments for complicated dam foundations.

Table2 China's as-built 200 m above double-curvature arch dams

2.2 A series of technologies for constructing 200-meter-high RCC gravity dams

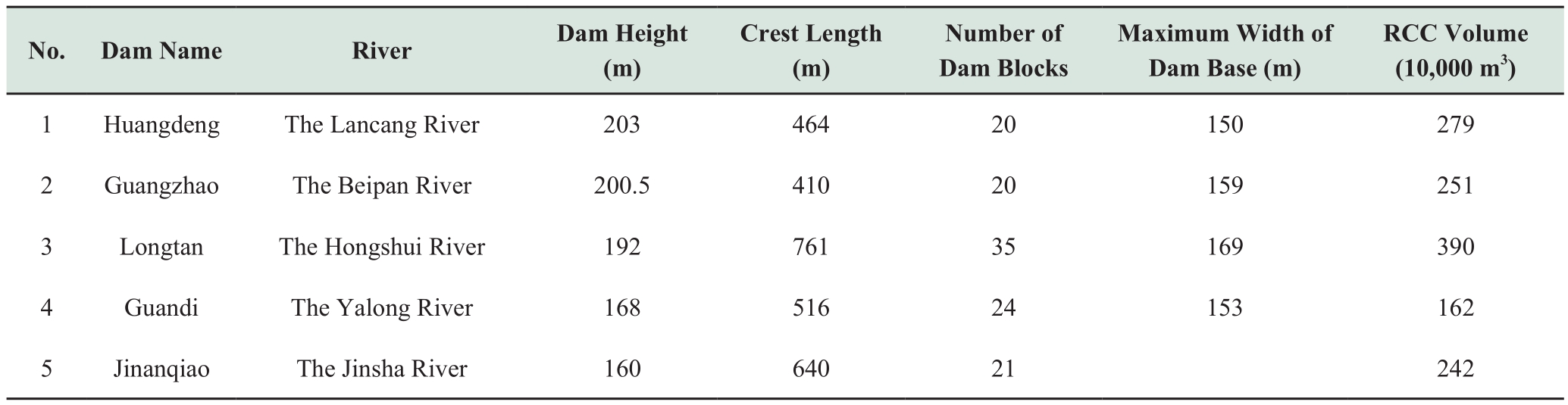

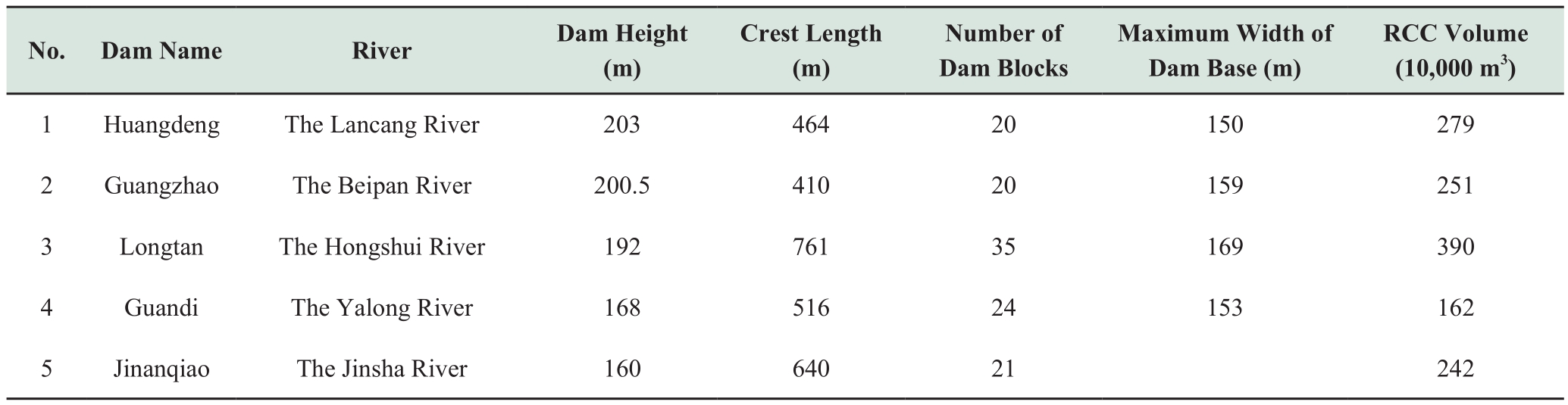

In recent years,China has successively built several 200-meter-extra-high RCC gravity dams,such as the Longtan,Guangzhao,Huangdeng,and Guandi Dams (Table3).

Similar to normal concrete gravity dams,massive geological explorations and calculation analyses shall be undertaken to ensure the sliding stability of the high RCC gravity dam foundations.Several studies and engineering practices bring into comprehensive seepage control technologies including direct seepage proof for grout enriched RCC and two-graded aggregate RCC,dam body seepage proof,and drainage systems.

Table3 China's as-built 200-meter-high RCC gravity dams

The extra-high RCC gravity dam reaches almost 170 m in terms of maximum base width and has a volume of almost 4 million m3.The challenges include ensuring the continuous and rapid construction of large-section full-face poured RCC and controlling the temperature in the hydration heat of the dam body.To effectively reduce such temperature spikes,some projects have adopted full-section RCC with threegraded aggregate technology; some others have adopted new technologies involving combined construction of normal concrete and RCC.The RCC materials,grading,and proportioning are thus continuously optimized.The intelligent temperature control system has developed rapidly.Furthermore,new generation communication,Internet of Things,three-dimensional simulation,high precision locating,and early warning and decision support technologies have also been applied in high RCC gravity dam construction.

In recent years,China has successively built several 200-meter-extra-high RCC gravity dams,such as the Longtan,Guangzhao,Huangdeng,and Guandi Dams (Table3).

Similar to normal concrete gravity dams,massive geological explorations and calculation analyses shall be undertaken to ensure the sliding stability of the high RCC gravity dam foundations.Several studies and engineering practices bring into comprehensive seepage control technologies including direct seepage proof for grout enriched RCC and two-graded aggregate RCC,dam body seepage proof,and drainage systems.

Table3 China's as-built 200-meter-high RCC gravity dams

The extra-high RCC gravity dam reaches almost 170 m in terms of maximum base width and has a volume of almost 4 million m3.The challenges include ensuring the continuous and rapid construction of large-section full-face poured RCC and controlling the temperature in the hydration heat of the dam body.To effectively reduce such temperature spikes,some projects have adopted full-section RCC with threegraded aggregate technology; some others have adopted new technologies involving combined construction of normal concrete and RCC.The RCC materials,grading,and proportioning are thus continuously optimized.The intelligent temperature control system has developed rapidly.Furthermore,new generation communication,Internet of Things,three-dimensional simulation,high precision locating,and early warning and decision support technologies have also been applied in high RCC gravity dam construction.

2.3 A series of technologies for constructing 200-m-high concrete face rockfill dams

Since the concept of the modern concrete face rockfill dam was introduced in 1985,China’s concrete face rockfill dam technologies have undergone continuous development based on international experiences.In recent years,China has built and put into operation a group of high concrete face rockfill dams exceeding 80 m in height; these include the Shuibuya and Houziyan dams and several others (Table4).At 233 m in height,the Shuibuya Dam is the world’s highest concrete face rockfill dam.

Table4 China's as-built 200-meter-high concrete face rockfill dams

Extra-high concrete face rockfill dams have better adaptability with regard to geological conditions of foundation compared to concrete dams,while the key point lies in the material reconnaissance and selection.Through extensive research and practical applications,China has managed to develop safety assessment technologies related to dam body safety,stability safety,and structure safety;several tests and theoretical studies have revealed the impact of material strength,grain breakage properties,complicated stress paths,and rockfill rheological properties on rockfill stress and deformation.Thus,China has conducted extensive research to establish rheological models,constitutive models for dam materials,refined calculation analysis methods,and relevant software.

The divisional design for dam bodies has been developed based on the new concept of the coordinated deformation of the dam body.The technologies and facilities,including direct graded aggregate production,large-tonnage rolling,extruding slope stabilization,gravity drainage at a reduced pressure in the upper reaches of the dam body during the construction period,toe board slip-form construction,copper water stop one-step molding,and several other methods,have been applied in dam construction.The application of such technologies in real-time monitoring systems for dam body filling and compaction processes and the use of the additive mass method for rapid rockfill density detection is beneficial during a rapid dam body construction process.The improvement of concrete face structures,the optimization of concrete proportions,the improvement of construction techniques,and the adoption of temperature and moisture preservation methods have prevented cracking and ensured the durability of the concrete face.The joint water stop generally consists of a self-healing structure with combined top and bottom and new materials.

Since the concept of the modern concrete face rockfill dam was introduced in 1985,China’s concrete face rockfill dam technologies have undergone continuous development based on international experiences.In recent years,China has built and put into operation a group of high concrete face rockfill dams exceeding 80 m in height; these include the Shuibuya and Houziyan dams and several others (Table4).At 233 m in height,the Shuibuya Dam is the world’s highest concrete face rockfill dam.

Table4 China's as-built 200-meter-high concrete face rockfill dams

Extra-high concrete face rockfill dams have better adaptability with regard to geological conditions of foundation compared to concrete dams,while the key point lies in the material reconnaissance and selection.Through extensive research and practical applications,China has managed to develop safety assessment technologies related to dam body safety,stability safety,and structure safety;several tests and theoretical studies have revealed the impact of material strength,grain breakage properties,complicated stress paths,and rockfill rheological properties on rockfill stress and deformation.Thus,China has conducted extensive research to establish rheological models,constitutive models for dam materials,refined calculation analysis methods,and relevant software.

The divisional design for dam bodies has been developed based on the new concept of the coordinated deformation of the dam body.The technologies and facilities,including direct graded aggregate production,large-tonnage rolling,extruding slope stabilization,gravity drainage at a reduced pressure in the upper reaches of the dam body during the construction period,toe board slip-form construction,copper water stop one-step molding,and several other methods,have been applied in dam construction.The application of such technologies in real-time monitoring systems for dam body filling and compaction processes and the use of the additive mass method for rapid rockfill density detection is beneficial during a rapid dam body construction process.The improvement of concrete face structures,the optimization of concrete proportions,the improvement of construction techniques,and the adoption of temperature and moisture preservation methods have prevented cracking and ensured the durability of the concrete face.The joint water stop generally consists of a self-healing structure with combined top and bottom and new materials.

2.4 A series of technologies for constructing 250-meter-high earth core rockfill dams

Chinese engineers have rapidly developed technologies related to the construction of high earth core wall rockfill dams,leading to the successive construction of dams such as Xiaolangdi,Pubugou,Nuozhadu,and Changheba (Table5).

Table5 China's as-built 250-meter-high earth core rockfill dams

High earth core wall rockfill dams measuring about 250 m and above impose lower requirements on the geological conditions of the foundation compared to concrete dams;however,they impose higher requirements in terms of exploration and testing for filling materials.A material yard reconnaissance method based on the P5 content isoline has been proposed,and the refined division of borrow pits has been realized,thus improving precision in reconnaissance.A series of in situ and laboratory tests have been performed;these included tests related to aggregate grading analysis,seepage deformation,consolidated quick shear,and dynamic strength for the filling materials.The controlled granular sizes of the maximum,fine aggregate,silt and cosmid for various dam construction materials were confirmed rationally.The designs of the dam body were divided as per the properties of the filling materials to control for compatible body deformation.

Generally,both the Duncan-Chang EB model and Shen Zhujiang’s double-yield surface elastoplastic model were adopted for conducting calculation analysis of the dam body deformation.The large-tonnage compacting machinery and the GPS-based digitalized dam filling monitoring system were adopted to monitor the types,weights,locations,speeds and rolling tracks,number of passes,and the status of construction machinery throughout the whole course and all day long.

Chinese engineers have rapidly developed technologies related to the construction of high earth core wall rockfill dams,leading to the successive construction of dams such as Xiaolangdi,Pubugou,Nuozhadu,and Changheba (Table5).

Table5 China's as-built 250-meter-high earth core rockfill dams

High earth core wall rockfill dams measuring about 250 m and above impose lower requirements on the geological conditions of the foundation compared to concrete dams;however,they impose higher requirements in terms of exploration and testing for filling materials.A material yard reconnaissance method based on the P5 content isoline has been proposed,and the refined division of borrow pits has been realized,thus improving precision in reconnaissance.A series of in situ and laboratory tests have been performed;these included tests related to aggregate grading analysis,seepage deformation,consolidated quick shear,and dynamic strength for the filling materials.The controlled granular sizes of the maximum,fine aggregate,silt and cosmid for various dam construction materials were confirmed rationally.The designs of the dam body were divided as per the properties of the filling materials to control for compatible body deformation.

Generally,both the Duncan-Chang EB model and Shen Zhujiang’s double-yield surface elastoplastic model were adopted for conducting calculation analysis of the dam body deformation.The large-tonnage compacting machinery and the GPS-based digitalized dam filling monitoring system were adopted to monitor the types,weights,locations,speeds and rolling tracks,number of passes,and the status of construction machinery throughout the whole course and all day long.

2.5 Technologies for facilitating large-flow discharge and energy dissipation

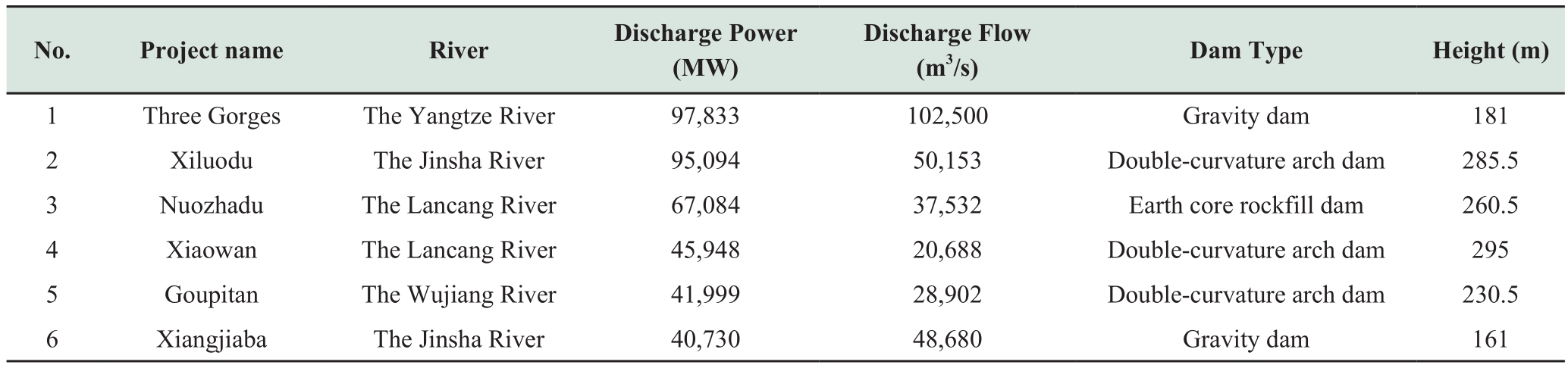

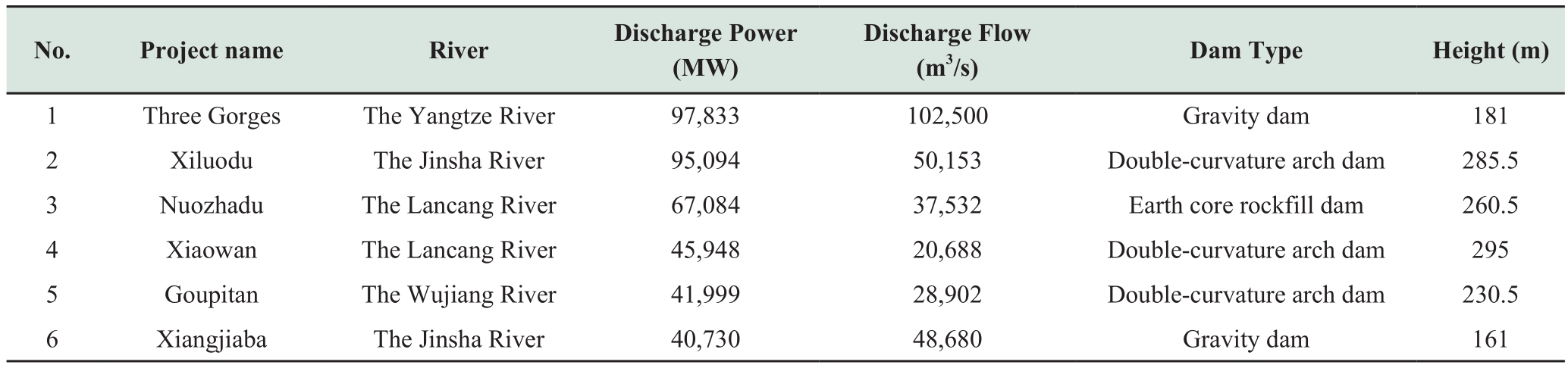

The challenge of the large-flow discharge of high dams in China calls for complex discharge structures,energy dissipation technologies,and scour prevention methods(Table6).

Table6 China's as-built hydropower stations with a discharge power exceeding 40,000 MW

An ultra-high or extra-high dam will inevitably face difficulties in terms of discharging large-flow flood waters with high head and dissipating energy.Gravity dams usually discharge water and dissipate energy through orifices in the dam body.Arch dams generally use dam orifices and bank tunnels to split the flood waters and dissipate the energy to different areas.All earth-rock dams adopt bank channels to discharge the flood waters.These dams’ designs are determined after a large number of discharge and energy dissipation schemes have been compared in combination with the project characteristics.Large-scale hydraulic model tests,decompression model tests,hydroelastic tests,and numerical simulation calculations give technical support to prevent cavitation and ensure the effectiveness of energy dissipation.With carefully designed concrete materials and optimized mix proportion,temperature rises of in terms of hydration heat,ultimate tensile value,volumetric deformation,and the drying shrinkage of the anti-scour concrete can be maintained within a reasonable range.Leveling and crack prevention methods are carried out on the concrete surface during construction.

The challenge of the large-flow discharge of high dams in China calls for complex discharge structures,energy dissipation technologies,and scour prevention methods(Table6).

Table6 China's as-built hydropower stations with a discharge power exceeding 40,000 MW

An ultra-high or extra-high dam will inevitably face difficulties in terms of discharging large-flow flood waters with high head and dissipating energy.Gravity dams usually discharge water and dissipate energy through orifices in the dam body.Arch dams generally use dam orifices and bank tunnels to split the flood waters and dissipate the energy to different areas.All earth-rock dams adopt bank channels to discharge the flood waters.These dams’ designs are determined after a large number of discharge and energy dissipation schemes have been compared in combination with the project characteristics.Large-scale hydraulic model tests,decompression model tests,hydroelastic tests,and numerical simulation calculations give technical support to prevent cavitation and ensure the effectiveness of energy dissipation.With carefully designed concrete materials and optimized mix proportion,temperature rises of in terms of hydration heat,ultimate tensile value,volumetric deformation,and the drying shrinkage of the anti-scour concrete can be maintained within a reasonable range.Leveling and crack prevention methods are carried out on the concrete surface during construction.

2.6 Construction technologies of huge underground cavern groups

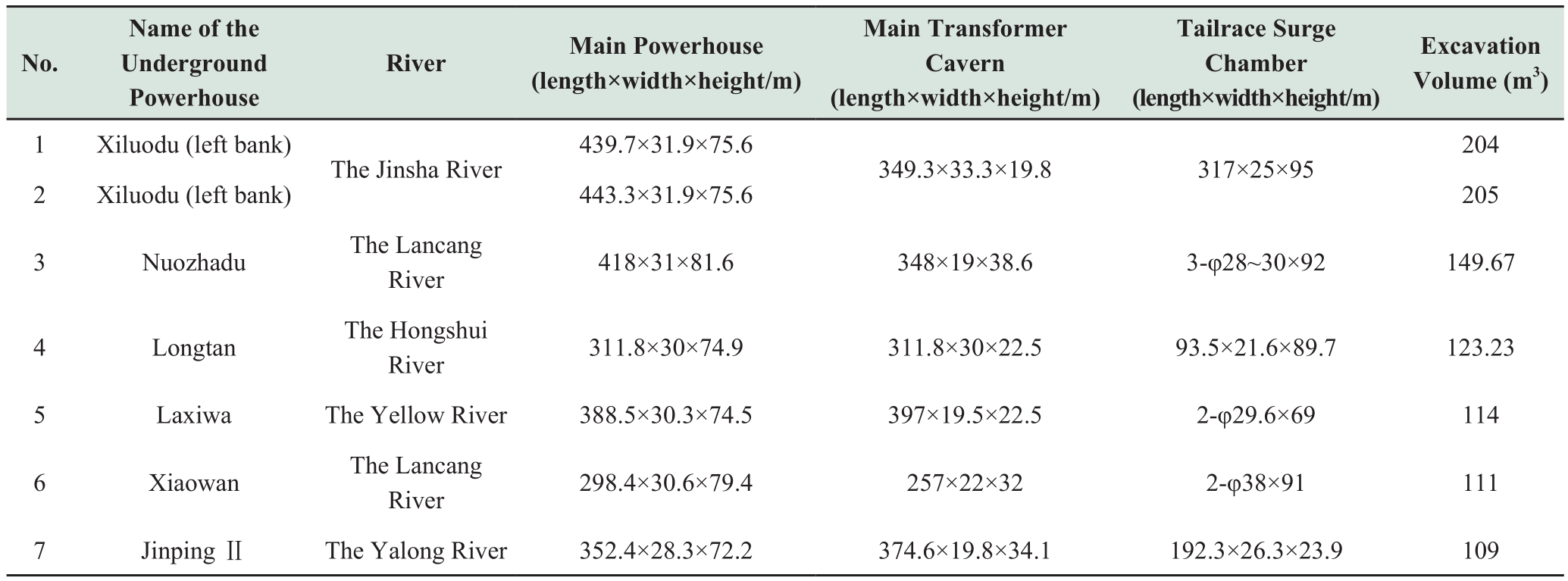

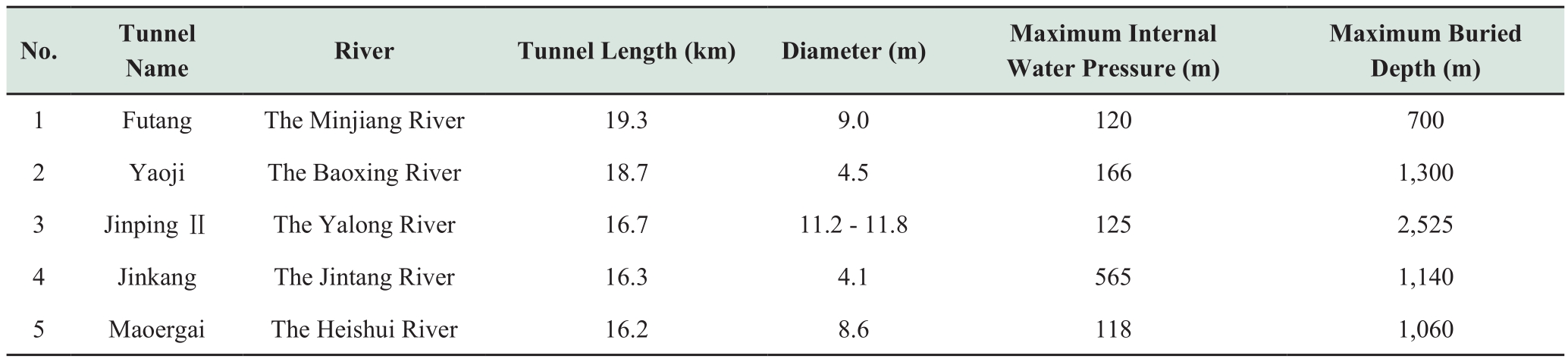

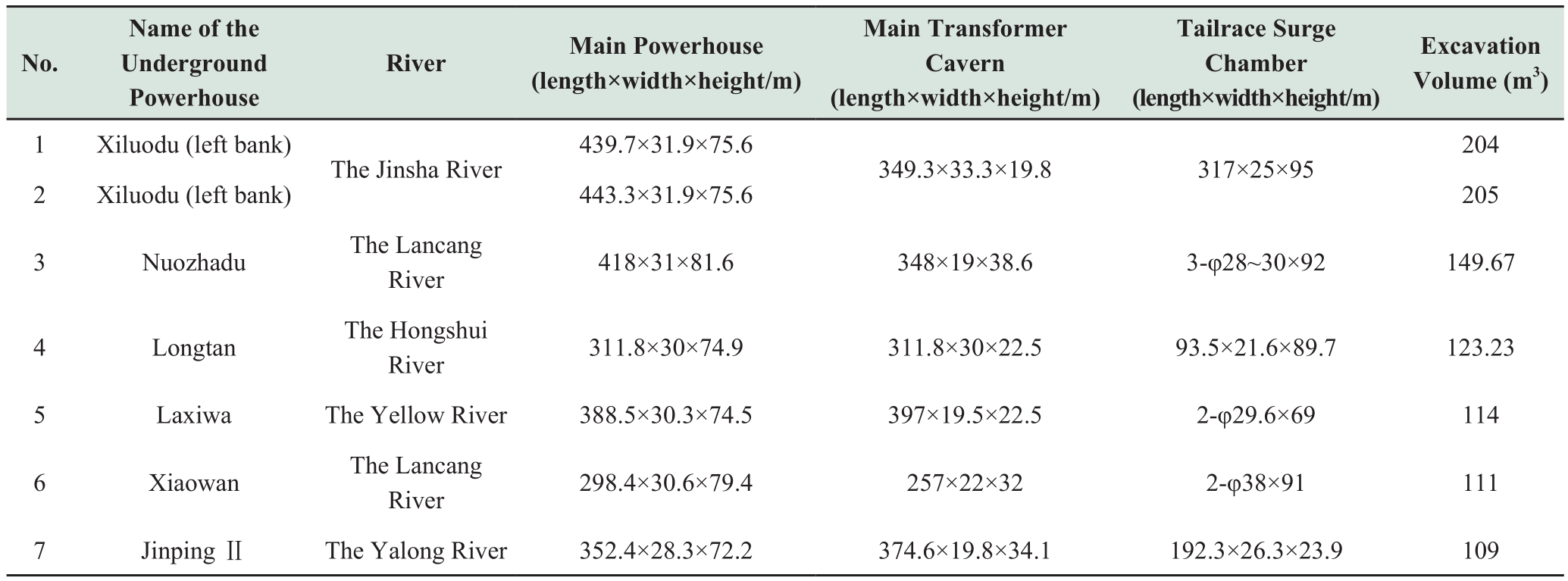

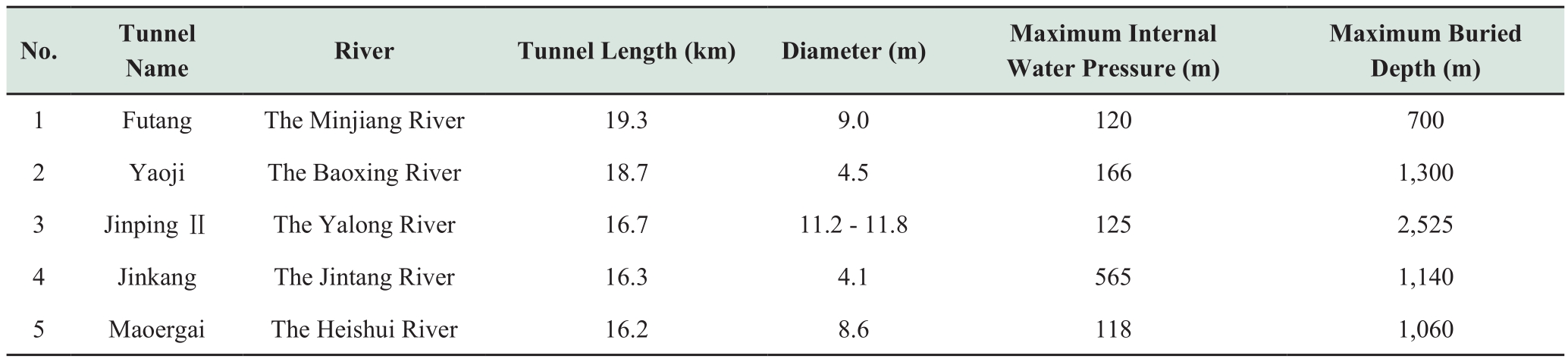

According to incomplete statistics,by the end of 2017,China had built more than 120 underground hydropower stations,and the total length of the underground headrace tunnel had reached about 1,100 km.Details about some of the huge underground powerhouses and super-long headrace tunnels of these hydropower stations are shown in Tables 7 and 8.

Table7 Some of the as-built huge underground powerhouses (excavation volume>1 million m3)

Table8 Some of the as-built underground headrace tunnels>16 km

These underground caverns are of mega scale,they have deeply buried depths,and they are also facing large ground stresses and complicated geological conditions.The superlong underground headrace tunnels have deep buried depths,long lengths,and large diameters; furthermore,they are characterized by large ground stresses and rich groundwater.Therefore,the construction of the underground cavern group has faced technical problems related to the stability of surrounding rocks,excavation and reinforcement,ventilation and smoke extraction,groundwater treatment,and large ground stresses.

In a huge underground cavern group,the layout of the main and auxiliary powerhouse caverns,main transformer caverns,and tailrace surge chambers should be reasonable.The thickness of the rock columns between caverns should suit the geological conditions; this will help to ensure the stability of the surrounding rock masses.Appropriate timing and the parameters for reinforcement design are adopted by analyzing the deformation and mechanical characteristics of the surrounding rock based on a reasonable assumption of failure law for the surrounding rocks and the anchoring mechanism of the reinforcement measures.

The stability of the cavern mainly depends on the self-stability ability of the surrounding rock masses and reinforcement measures,such as steel ribs,shotcrete anchoring and high-pressure consolidation grouting,and cavern reinforcement,which are dynamically adjusted according to the deformation and the stability of the surrounding rock masses during construction.Some countermeasures have been devised for dealing with geological problems such as large ground stress,rock burst,high-pressure large-flow water inrush,and karst development strata.Auxiliary adits should be properly arranged in accordance with the excavation and construction methods of the “multi processes in one plane and multi layers in the complex.” Ventilation and smoke extraction should be strengthened to keep construction safe.For these reasons,an advanced geological prediction system,composed of macro,both long-term and near-term,has been established.

According to incomplete statistics,by the end of 2017,China had built more than 120 underground hydropower stations,and the total length of the underground headrace tunnel had reached about 1,100 km.Details about some of the huge underground powerhouses and super-long headrace tunnels of these hydropower stations are shown in Tables 7 and 8.

Table7 Some of the as-built huge underground powerhouses (excavation volume>1 million m3)

Table8 Some of the as-built underground headrace tunnels>16 km

These underground caverns are of mega scale,they have deeply buried depths,and they are also facing large ground stresses and complicated geological conditions.The superlong underground headrace tunnels have deep buried depths,long lengths,and large diameters; furthermore,they are characterized by large ground stresses and rich groundwater.Therefore,the construction of the underground cavern group has faced technical problems related to the stability of surrounding rocks,excavation and reinforcement,ventilation and smoke extraction,groundwater treatment,and large ground stresses.

In a huge underground cavern group,the layout of the main and auxiliary powerhouse caverns,main transformer caverns,and tailrace surge chambers should be reasonable.The thickness of the rock columns between caverns should suit the geological conditions; this will help to ensure the stability of the surrounding rock masses.Appropriate timing and the parameters for reinforcement design are adopted by analyzing the deformation and mechanical characteristics of the surrounding rock based on a reasonable assumption of failure law for the surrounding rocks and the anchoring mechanism of the reinforcement measures.

The stability of the cavern mainly depends on the self-stability ability of the surrounding rock masses and reinforcement measures,such as steel ribs,shotcrete anchoring and high-pressure consolidation grouting,and cavern reinforcement,which are dynamically adjusted according to the deformation and the stability of the surrounding rock masses during construction.Some countermeasures have been devised for dealing with geological problems such as large ground stress,rock burst,high-pressure large-flow water inrush,and karst development strata.Auxiliary adits should be properly arranged in accordance with the excavation and construction methods of the “multi processes in one plane and multi layers in the complex.” Ventilation and smoke extraction should be strengthened to keep construction safe.For these reasons,an advanced geological prediction system,composed of macro,both long-term and near-term,has been established.

2.7 Complicated treatments for the foundation for high dams

High dam projects have always been characterized by complicated foundation treatments,which are represented by construction on the overburden.Some typical earth rockfill dams built on thick overburden foundations are shown in Table9.

Table9 Some of the typical earth rockfill dams built on thick overburden foundations

The key to successfully building a dam on a thick overburden is to figure out the distribution and main characteristics of the overburden; furthermore,it is important to evaluate the stability,including aspects such as sliding resistance,the seepage and deformation features of the embankment,and the foundation,through a series of static and dynamic tests and calculations.Treatments for thick overburden foundations include removal or reinforcement of the shallow-buried sand,construction of cutoff walls,and curtain grouting.After the long-term accumulations of practice and research,the fully enclosed treatment of high earth rockfill dams’ thick overburdens can be accomplished based on 200 m ultra-deep cutoff walls technology.Furthermore,a construction system for ultradeep cutoff walls by building orifices to form grooves under complicated and adverse geological conditions has been established,a technology to reinforce walls by using orifices and grooves has been developed,and innovations have been introduced into the concrete-casting walling technology.The maximum depth of these orifices and grooves can reach about 220 m in tests and 158 m in actual construction,and the maximum height of a dam built on a thick overburden foundation can reach 240 m.

High dam projects have always been characterized by complicated foundation treatments,which are represented by construction on the overburden.Some typical earth rockfill dams built on thick overburden foundations are shown in Table9.

Table9 Some of the typical earth rockfill dams built on thick overburden foundations

The key to successfully building a dam on a thick overburden is to figure out the distribution and main characteristics of the overburden; furthermore,it is important to evaluate the stability,including aspects such as sliding resistance,the seepage and deformation features of the embankment,and the foundation,through a series of static and dynamic tests and calculations.Treatments for thick overburden foundations include removal or reinforcement of the shallow-buried sand,construction of cutoff walls,and curtain grouting.After the long-term accumulations of practice and research,the fully enclosed treatment of high earth rockfill dams’ thick overburdens can be accomplished based on 200 m ultra-deep cutoff walls technology.Furthermore,a construction system for ultradeep cutoff walls by building orifices to form grooves under complicated and adverse geological conditions has been established,a technology to reinforce walls by using orifices and grooves has been developed,and innovations have been introduced into the concrete-casting walling technology.The maximum depth of these orifices and grooves can reach about 220 m in tests and 158 m in actual construction,and the maximum height of a dam built on a thick overburden foundation can reach 240 m.

2.8 Reinforcing high and steep slopes

The difficulty of excavating and reinforcing high and steep slopes is a prominent problem that challenges hydropower station construction in west China.Natural slopes with heights reaching up to 1,000 m and artificial slopes that rise hundreds of meters in height are distributed with large ground stresses and high seismic loads.Among the hydropower projects in China,the largest artificial slope is nearly 700 m in height,the largest ground stress is 34 MPa,and the maximum design for horizontal earthquake acceleration is 557.5 gal;such conditions pose extreme difficulties for the design and construction of projects in this region.

Table10 Typical high slope (>300 m) in hydropower stations in China

Based on the geomechanical model test,numerical analyses,and the development of construction techniques,China has accumulated a wealth of practical experience in the investigation,design,excavation,and reinforcement of high and steep slopes.It has adopted technical systems with regard to the deformation and stability analysis of high slopes,excavation and construction control,and system safety monitoring.The principle of “clearance on high elevation,the lowering of excavation lines,excavation to steep gradient,reinforcement with strengthened measures,and drainage from the deep” is summed up to ensure the stability of high slopes.

The difficulty of excavating and reinforcing high and steep slopes is a prominent problem that challenges hydropower station construction in west China.Natural slopes with heights reaching up to 1,000 m and artificial slopes that rise hundreds of meters in height are distributed with large ground stresses and high seismic loads.Among the hydropower projects in China,the largest artificial slope is nearly 700 m in height,the largest ground stress is 34 MPa,and the maximum design for horizontal earthquake acceleration is 557.5 gal;such conditions pose extreme difficulties for the design and construction of projects in this region.

Table10 Typical high slope (>300 m) in hydropower stations in China

Based on the geomechanical model test,numerical analyses,and the development of construction techniques,China has accumulated a wealth of practical experience in the investigation,design,excavation,and reinforcement of high and steep slopes.It has adopted technical systems with regard to the deformation and stability analysis of high slopes,excavation and construction control,and system safety monitoring.The principle of “clearance on high elevation,the lowering of excavation lines,excavation to steep gradient,reinforcement with strengthened measures,and drainage from the deep” is summed up to ensure the stability of high slopes.

3 Outlook

With the progress of the West-East Power Transmission Project,more mega- and large-scale hydropower projects are under construction or have been proposed in west China,including the regions surrounding the Jinsha River and the Yalong River (Table11).

Table11 Some of the large-scale hydropower stations under construction (installed capacity>2,000 MW)

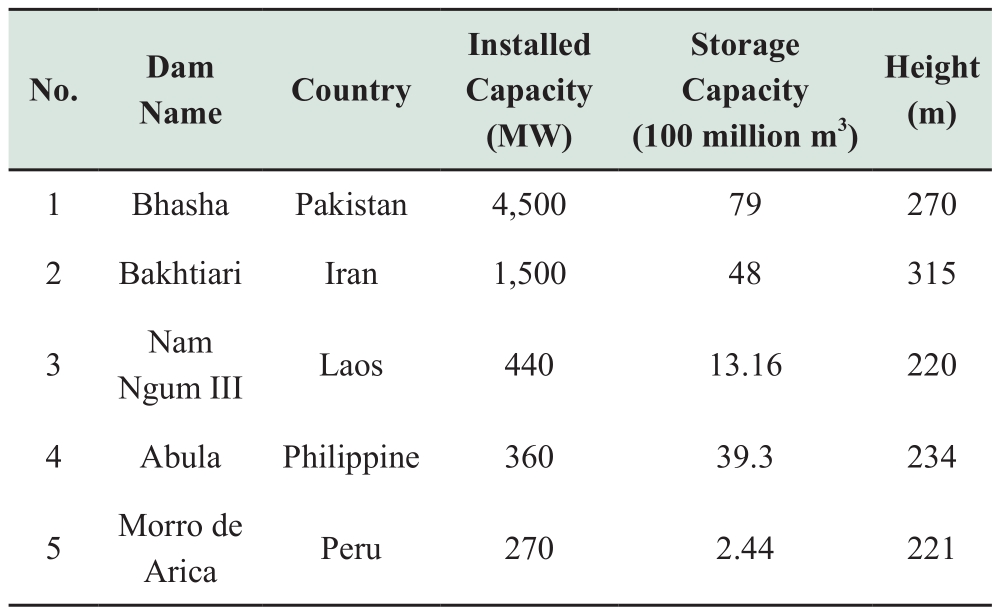

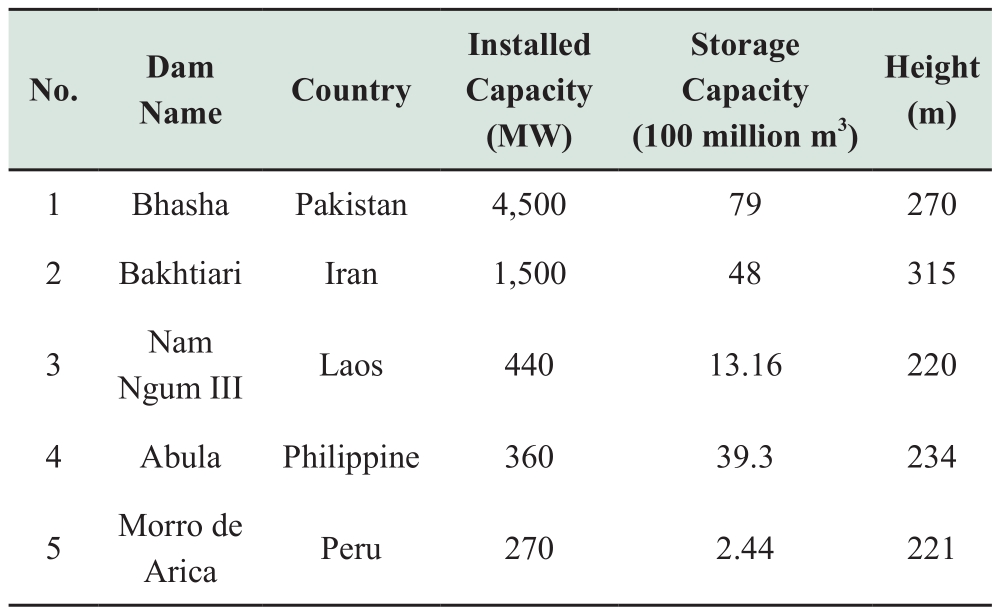

With the support of the Belt and Road Initiative,China will become more involved in the development of water resources worldwide,particularly in terms of high dam construction.Under-construction or proposed dams that are higher than 200 m are listed in Table12.

Table12 Some of the under-construction or proposed high dam projects (>200 m) (worldwide)

These domestic and international projects are to be built under severe natural conditions including high altitudes,low temperatures and anoxia,high temperatures and low pressures,and complicated topographical and geological backgrounds.There are also some technical difficulties in the construction of structures such as 300-meter-high concrete arch dams,200-meter-high RCC gravity dams,300-meter-high earth core rockfill dams,250-meter-high concrete face rockfill dams,large-flow discharge and energy dissipation,huge underground cavern groups,complicated foundation treatments,and reinforcements for high and steep slopes.These projects will provide China with opportunities to widely apply and further develop its leading technologies for hydropower development.

With the progress of the West-East Power Transmission Project,more mega- and large-scale hydropower projects are under construction or have been proposed in west China,including the regions surrounding the Jinsha River and the Yalong River (Table11).

Table11 Some of the large-scale hydropower stations under construction (installed capacity>2,000 MW)

With the support of the Belt and Road Initiative,China will become more involved in the development of water resources worldwide,particularly in terms of high dam construction.Under-construction or proposed dams that are higher than 200 m are listed in Table12.

Table12 Some of the under-construction or proposed high dam projects (>200 m) (worldwide)

These domestic and international projects are to be built under severe natural conditions including high altitudes,low temperatures and anoxia,high temperatures and low pressures,and complicated topographical and geological backgrounds.There are also some technical difficulties in the construction of structures such as 300-meter-high concrete arch dams,200-meter-high RCC gravity dams,300-meter-high earth core rockfill dams,250-meter-high concrete face rockfill dams,large-flow discharge and energy dissipation,huge underground cavern groups,complicated foundation treatments,and reinforcements for high and steep slopes.These projects will provide China with opportunities to widely apply and further develop its leading technologies for hydropower development.

4 Conclusions

(1) Since the implementation of the Reform and Opening-up Policy,especially the implementation of the West-East Power Transmission Project,numerous high dams and mega-scale hydropower stations have been built on the Yangtze River,the Jinsha River,the Lancang River,the Yalong River,the Dadu River,the Hongshui River,the Wujiang River,and several other rivers; these projects have greatly propelled the development of hydropower resources in China.

(2) After extensive efforts dedicated to learning advanced foreign technologies,building up experiences,and increasing long-term research and practice,China has finally found a new view with regard to independent intellectual property rights in the field of hydropower development.China now owns a series of construction technologies for 300-meter-high concrete arch dams,200-meter-high RCC gravity dams,200-meter-high concrete face rockfill dams,and 250-meter-high earth core rockfill dams; the country also owns leading technologies for facilitating large-flow discharge and energy dissipation,construction of huge underground cavern groups,complicated treatments for dam foundations,and reinforcements for high and steep slopes.

(3) Moreover,China plans to further develop hydropower resources in the high-altitude areas of west China,including the upper reaches of the Jinsha River and the Lancang River.At the same time,the country will be more involved in hydropower developments all over the world.It is expected that China’s leading-edge technologies will be widely used and further developed in these domestic and international hydropower projects and that these projects will provide the country with the opportunity to make even greater contributions toward global development.

References

[1]ISO study of operational requirements and market impacts at 33% RPS.CPUC workshop on CAISO and PG&E renewable integration model methodologies,24 Aug 2010

[2]Kell G (2018) GEI - An idea whose time has come.Global Energy Interconnection,1(1):1-3

[3]Voropai N,Podkovalnikov S,Osintsev K (2018) From interconnections of local electric power systems to Global Energy Interconnection.Global Energy Interconnection.1(1):4-10

[4]Yamaguchi S,Iitsuka T,Osada M,Yokoyama R(2018)Asian international grid connection and potentially of DC superconducting power transmission.Global Energy Interconnection,1(1):11-19

[5]Shen H,Dai Q,Wu Q,Wu J,Zhou Q,Wang J,Yang W,Pestana R,Pastor R (2018) The state-of-the-arts of the study on grid interconnection between Iberian Peninsula and West Maghreb region.Global Energy Interconnection,1(1):20-28

[6]Gao C,Ding X,Tang G,Wang G,Qiu P (2018) Key stress extraction and equivalent test method for hybrid DC circuit breaker.Global Energy Interconnection,1(1):29-38

[7]Zhang D,Chan C,Zhou Y (2018) Enabling Industrial Internet of Things (IIoT) towards and emerging smart energy system.Global Energy Interconnection,1(1):39-47

[8]Kåberger T (2018) Progress of renewable electricity replacing fossil fuels.Global Energy Interconnection,1(1):48-52

[9]Zhao L,Wang W,Zhu L,Liu Y,Dubios A (2018) Economic analysis of solar energy development in North Africa.Global Energy Interconnection,1(1):53-62

[10]Yang Z,Liu H,Bi T,Yang Q,Xue A(2018) A PMU data recovering method based on preferred selection strategy.Global Energy Interconnection,1(1):63-69

[11]Yang Y,Bie Z,Qiu A (2018) A review of key strategies in realizing power system resilience.Global Energy Interconnection,1(1):70-78

[12]Guo B,Niu M,Lai X,Chen L (2018) Application research on large-scale battery energy storage system under Global Energy Interconnection framework.Global Energy Interconnection,1(1):79-86

[13]Liang X (2018) Application and research of global grid database design based on geographic information.Global Energy Interconnection,1(1):87-95

[14]Liu Y,Tian H,Liu Z,Qin X (2018) Aspects of ultra-high voltage half-wavelength power transmission technology.Global Energy Interconnection,1(1):96-102

(1) Since the implementation of the Reform and Opening-up Policy,especially the implementation of the West-East Power Transmission Project,numerous high dams and mega-scale hydropower stations have been built on the Yangtze River,the Jinsha River,the Lancang River,the Yalong River,the Dadu River,the Hongshui River,the Wujiang River,and several other rivers; these projects have greatly propelled the development of hydropower resources in China.

(2) After extensive efforts dedicated to learning advanced foreign technologies,building up experiences,and increasing long-term research and practice,China has finally found a new view with regard to independent intellectual property rights in the field of hydropower development.China now owns a series of construction technologies for 300-meter-high concrete arch dams,200-meter-high RCC gravity dams,200-meter-high concrete face rockfill dams,and 250-meter-high earth core rockfill dams; the country also owns leading technologies for facilitating large-flow discharge and energy dissipation,construction of huge underground cavern groups,complicated treatments for dam foundations,and reinforcements for high and steep slopes.

(3) Moreover,China plans to further develop hydropower resources in the high-altitude areas of west China,including the upper reaches of the Jinsha River and the Lancang River.At the same time,the country will be more involved in hydropower developments all over the world.It is expected that China’s leading-edge technologies will be widely used and further developed in these domestic and international hydropower projects and that these projects will provide the country with the opportunity to make even greater contributions toward global development.

References

[1]ISO study of operational requirements and market impacts at 33% RPS.CPUC workshop on CAISO and PG&E renewable integration model methodologies,24 Aug 2010

[2]Kell G (2018) GEI - An idea whose time has come.Global Energy Interconnection,1(1):1-3

[3]Voropai N,Podkovalnikov S,Osintsev K (2018) From interconnections of local electric power systems to Global Energy Interconnection.Global Energy Interconnection.1(1):4-10

[4]Yamaguchi S,Iitsuka T,Osada M,Yokoyama R(2018)Asian international grid connection and potentially of DC superconducting power transmission.Global Energy Interconnection,1(1):11-19

[5]Shen H,Dai Q,Wu Q,Wu J,Zhou Q,Wang J,Yang W,Pestana R,Pastor R (2018) The state-of-the-arts of the study on grid interconnection between Iberian Peninsula and West Maghreb region.Global Energy Interconnection,1(1):20-28

[6]Gao C,Ding X,Tang G,Wang G,Qiu P (2018) Key stress extraction and equivalent test method for hybrid DC circuit breaker.Global Energy Interconnection,1(1):29-38

[7]Zhang D,Chan C,Zhou Y (2018) Enabling Industrial Internet of Things (IIoT) towards and emerging smart energy system.Global Energy Interconnection,1(1):39-47

[8]Kåberger T (2018) Progress of renewable electricity replacing fossil fuels.Global Energy Interconnection,1(1):48-52

[9]Zhao L,Wang W,Zhu L,Liu Y,Dubios A (2018) Economic analysis of solar energy development in North Africa.Global Energy Interconnection,1(1):53-62

[10]Yang Z,Liu H,Bi T,Yang Q,Xue A(2018) A PMU data recovering method based on preferred selection strategy.Global Energy Interconnection,1(1):63-69

[11]Yang Y,Bie Z,Qiu A (2018) A review of key strategies in realizing power system resilience.Global Energy Interconnection,1(1):70-78

[12]Guo B,Niu M,Lai X,Chen L (2018) Application research on large-scale battery energy storage system under Global Energy Interconnection framework.Global Energy Interconnection,1(1):79-86

[13]Liang X (2018) Application and research of global grid database design based on geographic information.Global Energy Interconnection,1(1):87-95

[14]Liu Y,Tian H,Liu Z,Qin X (2018) Aspects of ultra-high voltage half-wavelength power transmission technology.Global Energy Interconnection,1(1):96-102

Scan for more details

Received:9 March 2018/ Accepted:20 April 2019/ Published:25 June 2019

Zeyan Yang

12712625002@qq.com

Chao Liu

nickliu04@qq.com

Mingxin Wu

wumx05@foxmail.com

2096-5117/© 2019 Global Energy Interconnection Development and Cooperation Organization.Production and hosting by Elsevier B.V.on behalf of KeAi Communications Co.,Ltd.This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/ ).

Acknowledgments

This work was supported by the National Key Basic Research Development Plan (973 Plan) (2013CB036400).

Biographies

Zeyan Yang received bachelor degree of Engineering at Gezhouba Hydropower Engineering College (now Three Gorges University),Yichang,1983; received master of Engineering degree at Wuhan University,Wuhan,2006.He received the reward of National Engineering Survey and Design in 2016.He is currently the Chief Deputy Engineer of China Renewable Energy Engineering Institute.He is engaged in the design and construction of hydraulic structures,geotechnical engineering and safety monitoring.

Chao Liu received bachelor degree at Tsinghua University,Beijing,2008; received Ph.D.degree at Tsinghua University,Beijing,2014.He is working in China Renewable Energy Engineering Institute,Beijing.He has taken part in research and design of several high rockfill dams in China such as Lianghekou,Changheba,Jishixia,and Jinchuan,etc.

Mingxin Wu received bachelor degree at Tsinghua University,Beijing,2009; received Ph.D.degree at Tsinghua University,Beijing,2015.She is working in China Renewable Energy Engineering Institute,Beijing.Her research interests include seismic design of concrete dam and dynamic behavior of concrete.

(Editor Zhou Zhou)